description

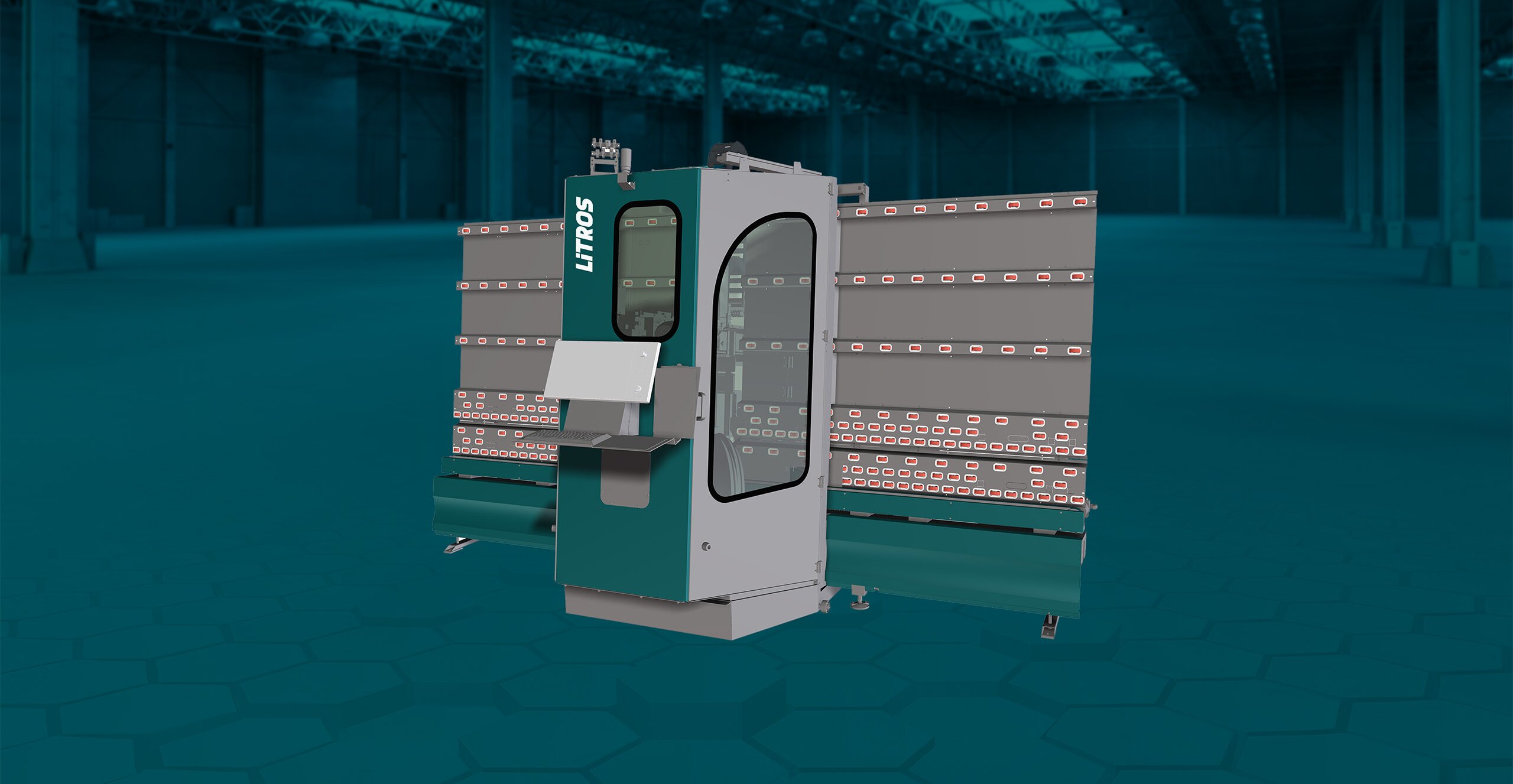

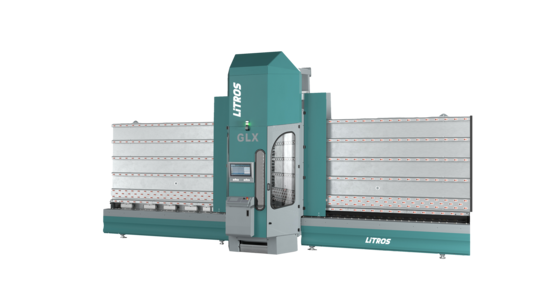

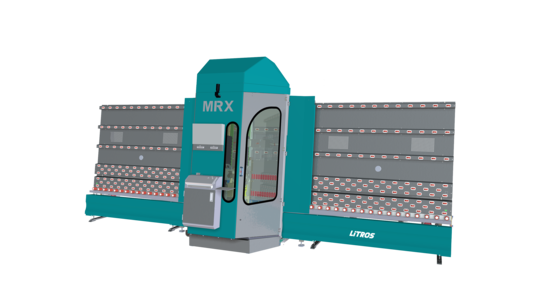

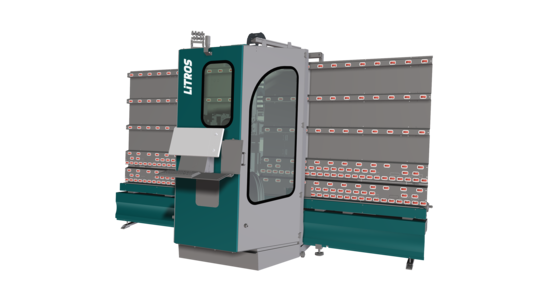

LiTROS Topdrill RX G8

Thanks to the eight-fold turret, Topdrill RX G8 is perfect for quickly drilling and lowering flat glass, and can also create surface and edge cuts very economically thanks to the optional waterjet head.

Like all G8 systems, the RX can be used as an individual device or as part of the COMBIFIN line.

LiTROS Topdrill RX G8 is available in two versions:

- Topdrill RX 14 G8

- Topdrill RX 25 G8

The machine consists of:

Massive base frame (G8 series)

Front and rear Y-bar for precise movement of drill heads

Y-axis drive either with a belt or ball screw

Extension modules

Side maintenance accesses

Model RX 14: Open-facing design

Model RX 25: Closed at the top

LiTROS Topdrill RX G8

Highlights

01

Easy operation and suitable for Industry 4.0

The intuitive control system and modern interfaces enable easy use and seamless integration into digital processes.

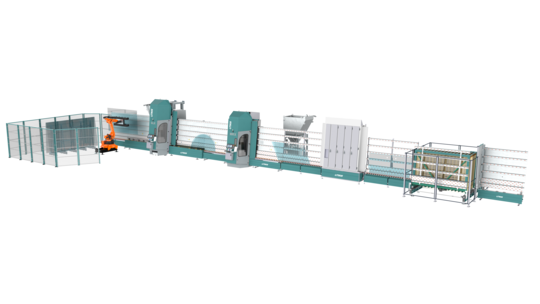

Precise and fully automated processing

Whether as a single device or combined with GLX grinding machines and TopClear washing systems — the RX machine adapts to any production environment.

Can be flexibly integrated into processing lines

Thanks to CNC control and automatic measurement of tool length and glass thickness, processing is accurate and efficient.

Versatile thanks to waterjet option

With the optional water jet head, individual edge and surface cutouts as well as holes in variable diameters can be flexibly implemented.

Perfectly coordinated

Function & procedure

01

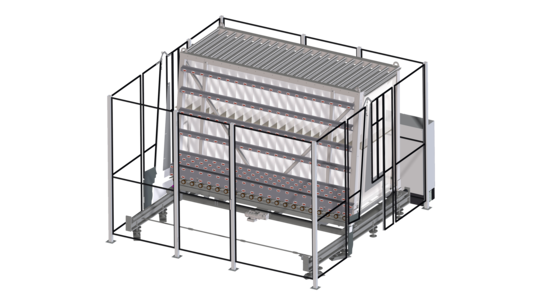

How is the Topdrill RX G8 constructed?

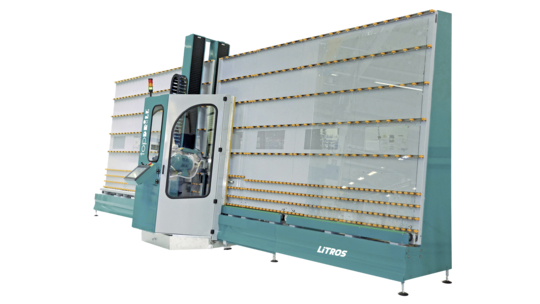

The RX machine is based on the robust base frame of the G8 series and allows flexible combinations of heights, drill heads and body lengths. Y-bars, safety cladding and control cabinet are fully integrated. Depending on the application, the Y-axis can be equipped with a belt drive or ball screws. The system can be assembled to save space, can be maintained laterally and can be extended with extension modules. It can be combined with GLX grinding machines and TopClear washing systems, and the running direction can be freely selected.

02

How does the Topdrill RX G8 work?

The RX drilling machine is a vertical device for drilling and lowering flat glass on both sides, with optional waterjet cutting. It offers flexible data entry, automatic measurement and optimized drilling process. Tools can be changed during operation, and coated glasses and special shapes are easy to process. With a waterjet head, complex cut-outs are also possible — ideal for applications such as shower or all-glass doors.

03

Who is the Topdrill RX G8 suitable for?

The Topdrill RX series is suitable for every modern glass processing company. Thanks to the various processing heights and the variable extension modules, the machine can be optimally adapted to local conditions and requirements. The ideal area of application for the RX 16 model is the production of shower and all-glass doors, side panels, balustrades or similar glasses. With this model, too, the maximum glass length can be adjusted using extension modules.

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?