description

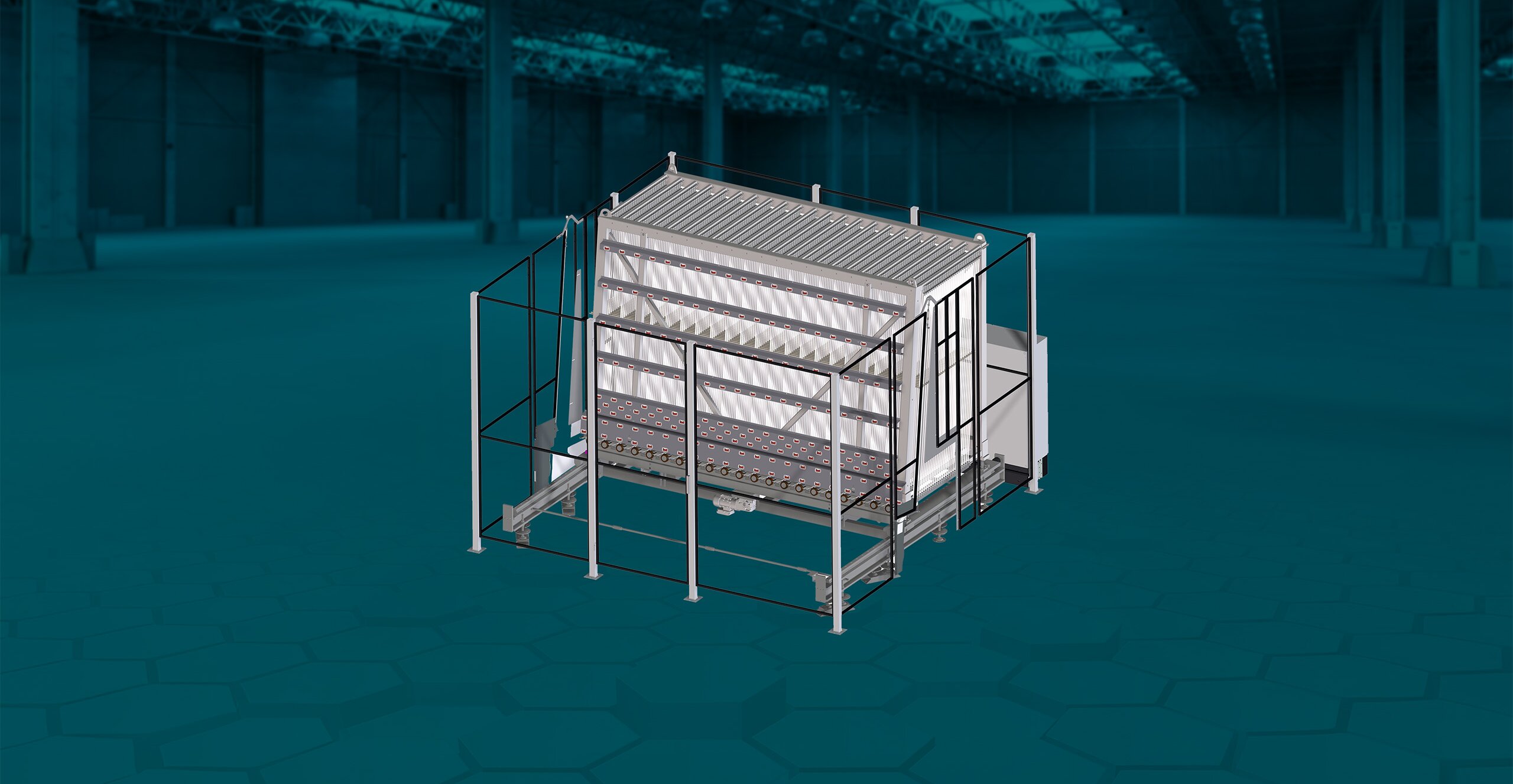

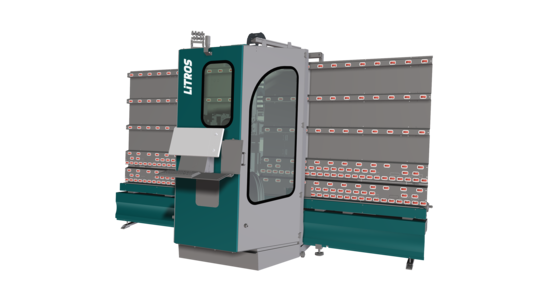

LiTROS SSP-A

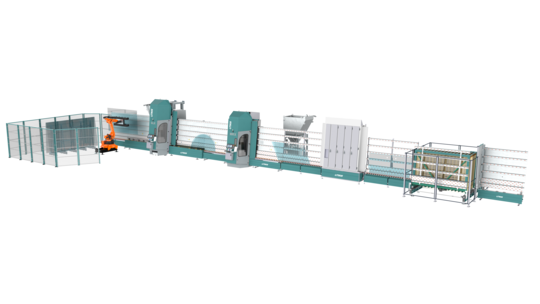

The LiTROS SSP-A sorting and storage buffer is the ideal addition to vertical processing machines. The system offers 30 individually controllable storage compartments, and each compartment can be filled with up to 4 glass sheets. Loading is carried out via loading modules or directly via the processing machine. The particular advantage of SSP is the completely unmanned loading, which prevents unnecessary downtimes.

The SSP-A is available in two sizes and can be used for loading or unloading.

The machine consists of:

Base frame with guide rails

Monoblock frame with storage compartments

Transport carrier

LiTROS SSP-A

Highlights

01

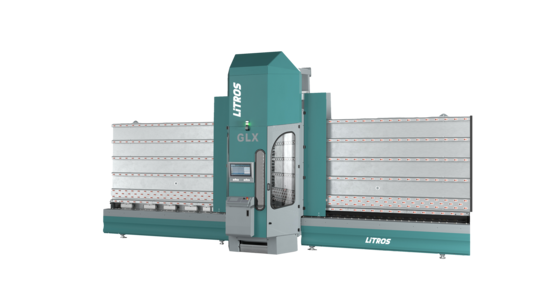

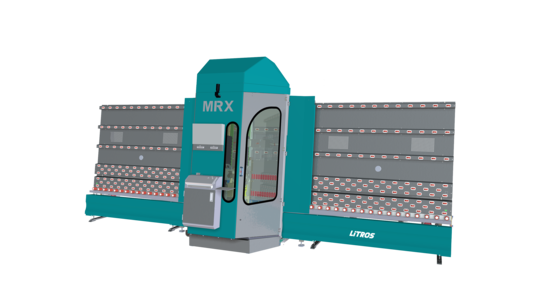

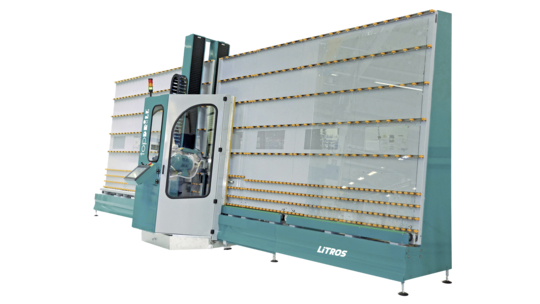

System compatibility:

Optimally designed for integration into CombiFin or M-RX G7 or RX G8.

Wide range of formats:

It is possible to store and export mixed sizes, shapes and thicknesses.

Networked process control:

Direct communication and networking with the neighboring machine.

Flexible use:

Can be used for loading or unloading (defined in advance).

Increasing efficiency:

Optimizes the use of the processing machine, speeds up the process

Transparent process control:

Constant overview of inventory status and remaining working time

Efficient, flexible, networked and reliable

Function & procedure

01

How is the SSP-A structured?

The SSP-A sorting and storage buffer is specifically designed for loading or unloading the CombiFin processing line. It consists of a sturdy base frame with guide rails and a torsion-resistant monoblock frame with storage compartments, which are divided by a grid bar system. The frame moves along the axis, and a movably stored transport carrier specifically operates the selected storage compartment. The storage compartments are tilted by 7 degrees — suitable for the processing machine. A safety fence and a flexibly mountable control terminal are also part of the system.

02

How does the SSP-A sorting and storage buffer work?

The SSP-A serves as an intelligent buffer for optimal utilization of the processing machine. Stored glasses are clearly identified and checked in advance. It is operated via an 18.5" TFT color display with synchronized input to the following machine. The necessary interface is included. Depending on the configuration, the SSP is controlled for loading or unloading. Data can be imported directly or via an ERP system. Different formats and glass thicknesses as well as special shapes are possible.

03

Who is an SSP-A suitable for?

The SSP sorting and storage buffer is of interest to all companies that have continuous production and have a vertical production plant. The SSP ensures that there are no unnecessary waiting times or downtimes, for example because there is no operator at the system or is employed for other tasks. The performance of the processing machine is optimized and increased. Through structured operation, the SSP optimizes the entire workflow in the environment.

04

What are the benefits of the system?

The SSP-A sorting and storage buffer ensures optimal use of processing machines and prevents unnecessary and unplanned waiting times. The following disk is loaded onto the processing machine immediately after the inflow path has been cleared. The data is synchronized between the two systems and each system (depending on the available software connection) can also report the status to higher-level systems.

Specifications

LiTROS SSP-A

Here you can find all relevant features of our machine.

contact

Overall size: 3575 x 4600 mm, height 2700 mm

Maximum dimensions: 3200 x 2000 mm

Minimum dimensions: 700 x 400 mm

Maximum warping: 3 mm

Glass barrel height: 630 mm, inclination 7°

Configuration: 30 individual storage compartments, up to 4 glasses per compartment, front panel as an inlet extension

Cycle time: max. 50 seconds per cycle or withdrawal

Transport speed: up to 20 m/min

Low-E glass: processable

Compatibility: with CombiFin, M-RX G7, RX G8

Installed power: 1.5 kW

Total weight: 1200 kg

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?