description

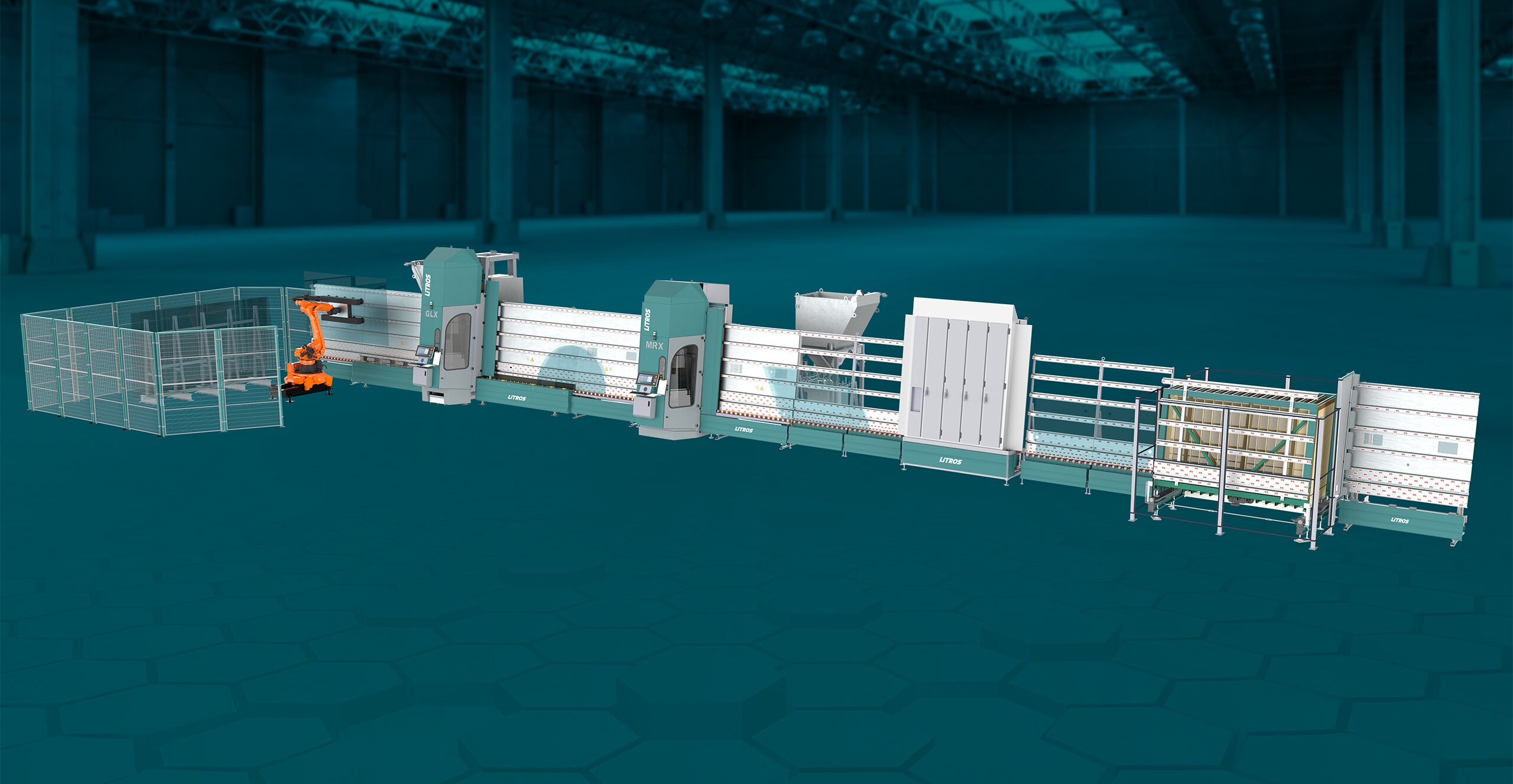

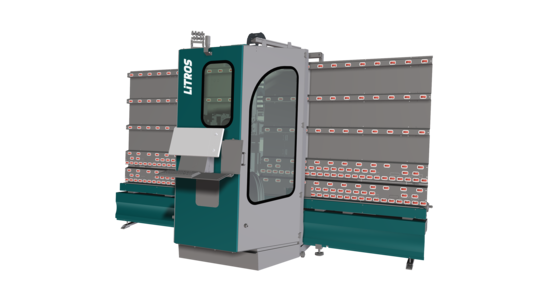

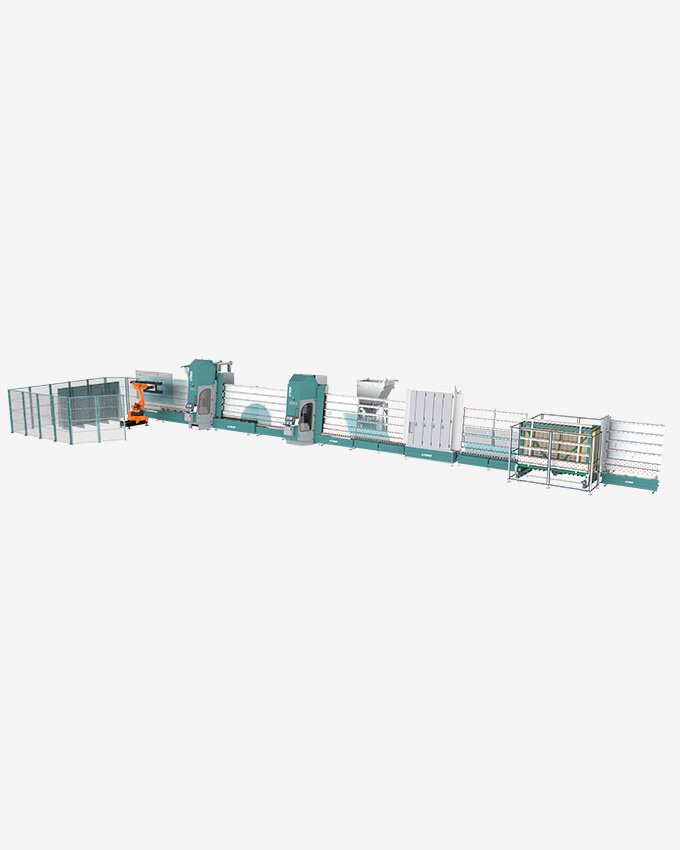

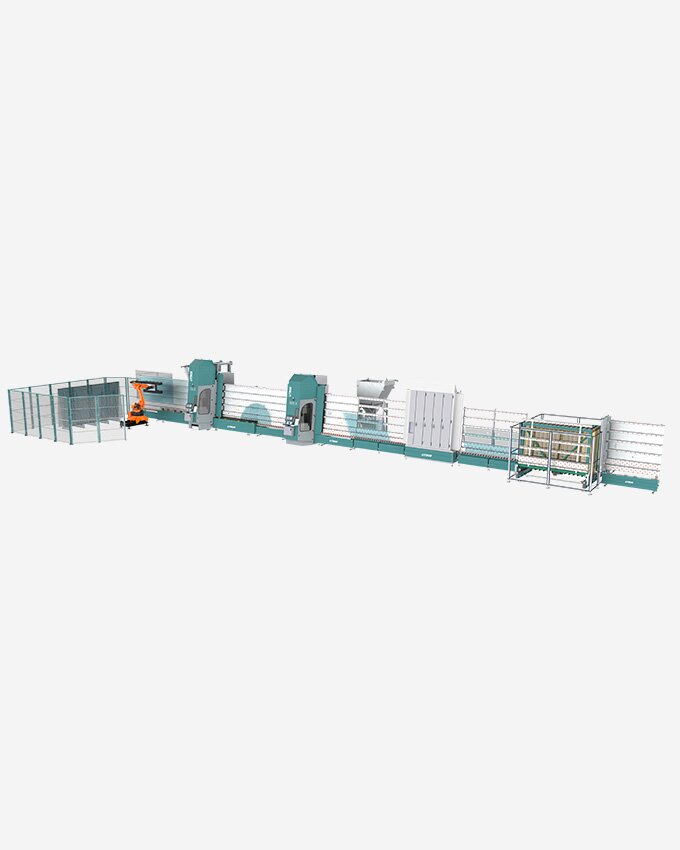

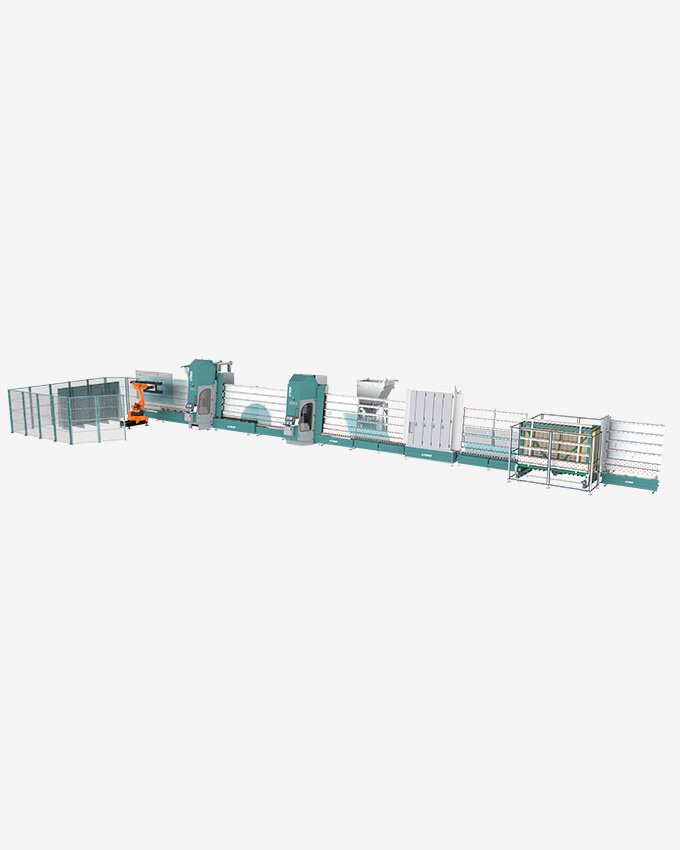

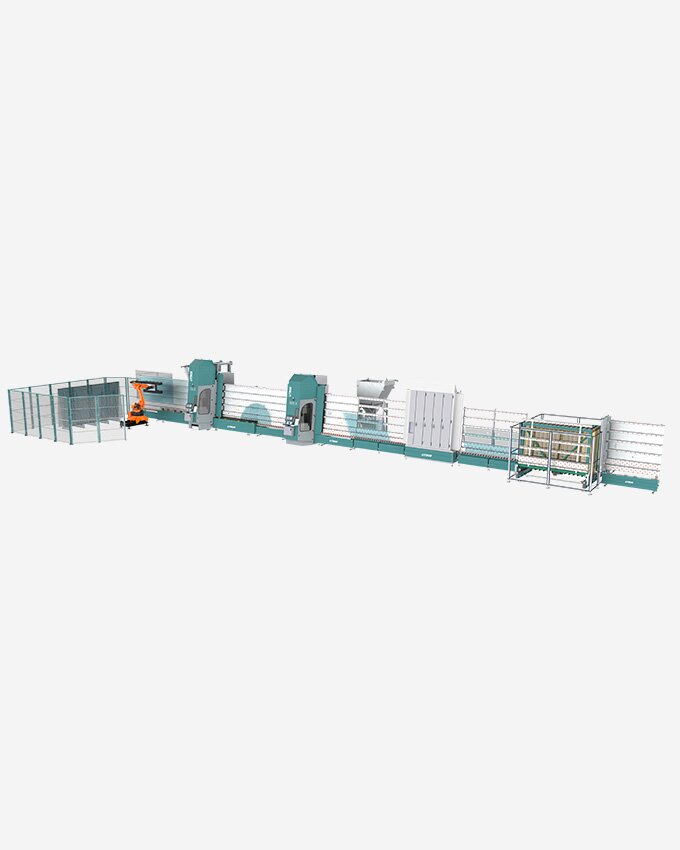

LiTROS Combifin

LiTROS Combifin is the fastest and easiest way to vertically process medium-sized glass formats while maintaining optimum cycle time and efficiency.

Components of the system

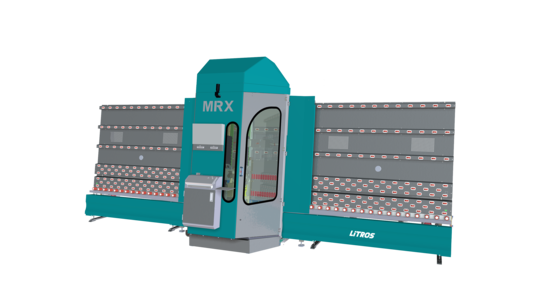

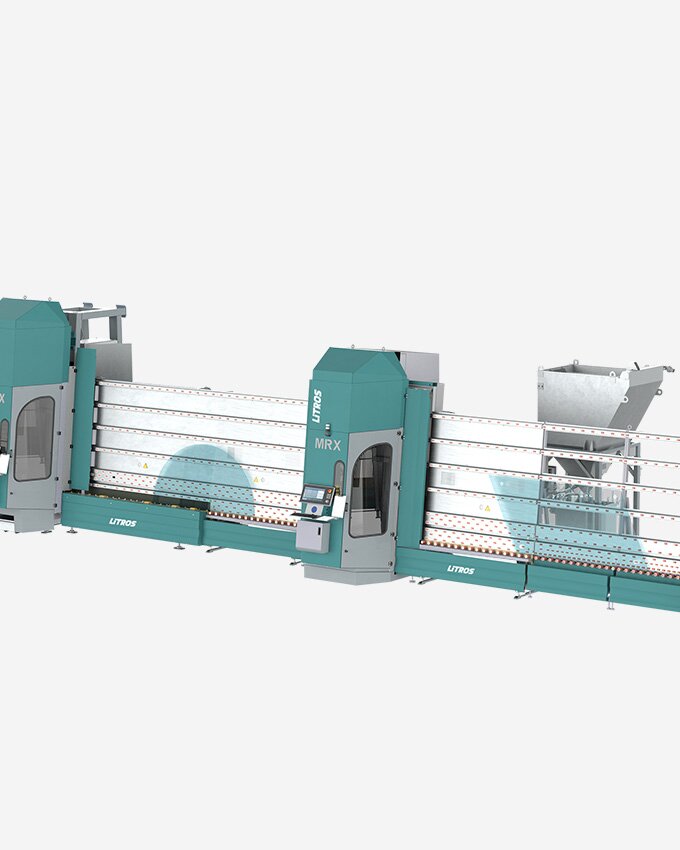

LiTROS MRX G7

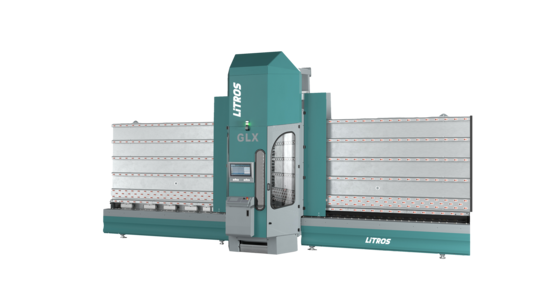

LiTROS GLX P1

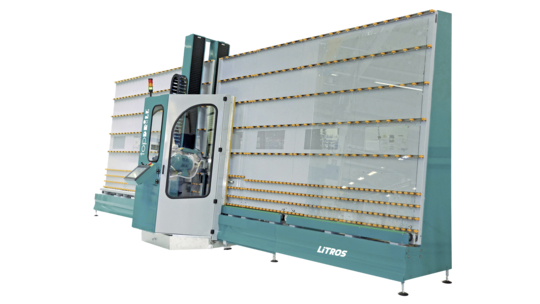

LiTROS Float Break

Highlights

01

Peak cycle times for maximum efficiency

Thanks to the combination of machines, downtimes are avoided — typical glass products such as shower doors are ready in less than five minutes.

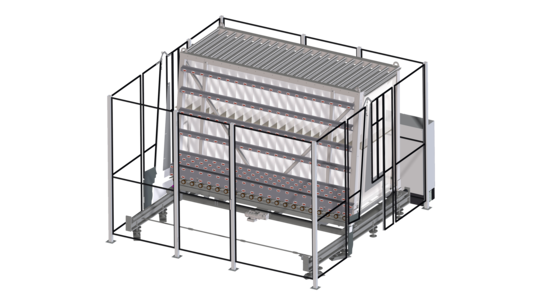

Compact design with vertical processing

The space-saving construction enables gentle glass transport and easy loading and unloading thanks to the vertical orientation.

Flexibility in shapes and sizes

Whether rectangles or special shapes — even with batch size 1, mixed production is possible without loss of cycle time. Tool changes take place automatically during the suction phase.

Processing without changing tools

Coarse, fine and polish are carried out in one go — this saves time and increases process reliability.

Intelligent software integration for smooth processes

Modern functions such as DXF import, automatic data distribution and remote maintenance enable efficient, user-friendly control without manual intervention.

Energy-efficient and technologically advanced

Integrated vacuum generation and modern spindle technology with water cooling ensure maximum energy efficiency.

Expandable and fail-safe

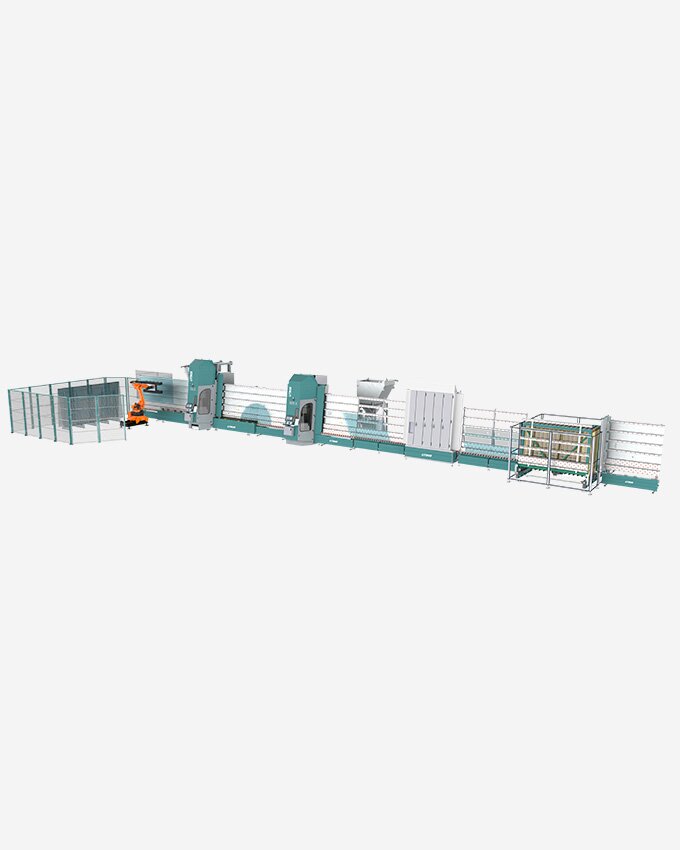

Individual devices can be used independently, running direction can be selected — the system can be flexibly combined with washing machines or logistics solutions.

Perfectly coordinated

Function & procedure

01

How is the processing line structured?

LiTROS Combifin combines intelligent processing devices into a logical unit and also enables the individual components to be used independently. Typically, the line is made up of a LiTROS GLX P1 grinding and polishing machine formed in combination with an MRX G7 drilling and milling center. Instead of the MRX G7, a LiTROS Topdrill drilling machines will be used, soon also with patented waterjet technology as additional equipment. All devices are CNC controlled. The range is supplemented with Topclear washing machines and mechanical water treatment systems.

02

How does the GLX P1 grinding and polishing machine work?

A central and important area of glass processing is the grinding and polishing of outer edges. With the GLX P1, almost all shapes can be externally processed, with only a straight standing edge being required. Compared to all-in-one machines, the GLX P1 is significantly faster and, of course, much easier to operate. Despite full line integration, the GLX P1 can also be used as a standalone device if required.

03

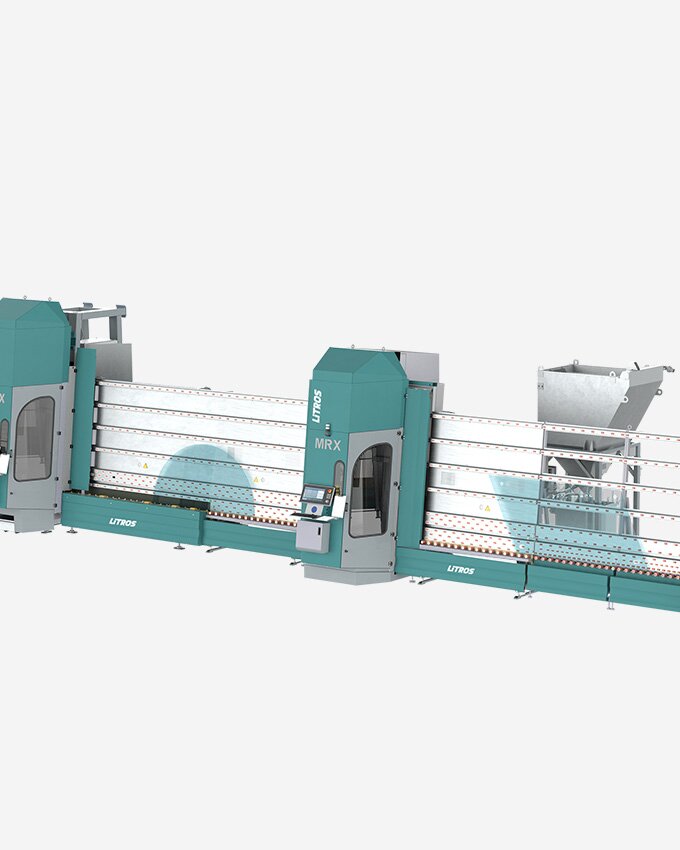

How does the MRX G7 work?

The MRX G7 is a well-known system for flexible drilling, sinking and milling operations. Internal processing with drilling, countersinking, milling and grinding offers unbeatable variability and extreme performance in two-sided machining.

04

Who is the processing line suitable for?

DLiTROS Combifin is the perfect processing solution for all companies with a continuous need for different types of glass, even in batch sizes = 1. All-glass doors, back walls, balustrades or partitions cannot be processed faster and more easily than with the LiTROS Combifin line.

05

What are the advantages of the combination line?

The benefits of LiTROS Combifin combination lines offer extreme performance combined with flexibility and very simple operation. Thanks to consistent standardization and series production, the system is maintenance-friendly and inexpensive.

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?