description

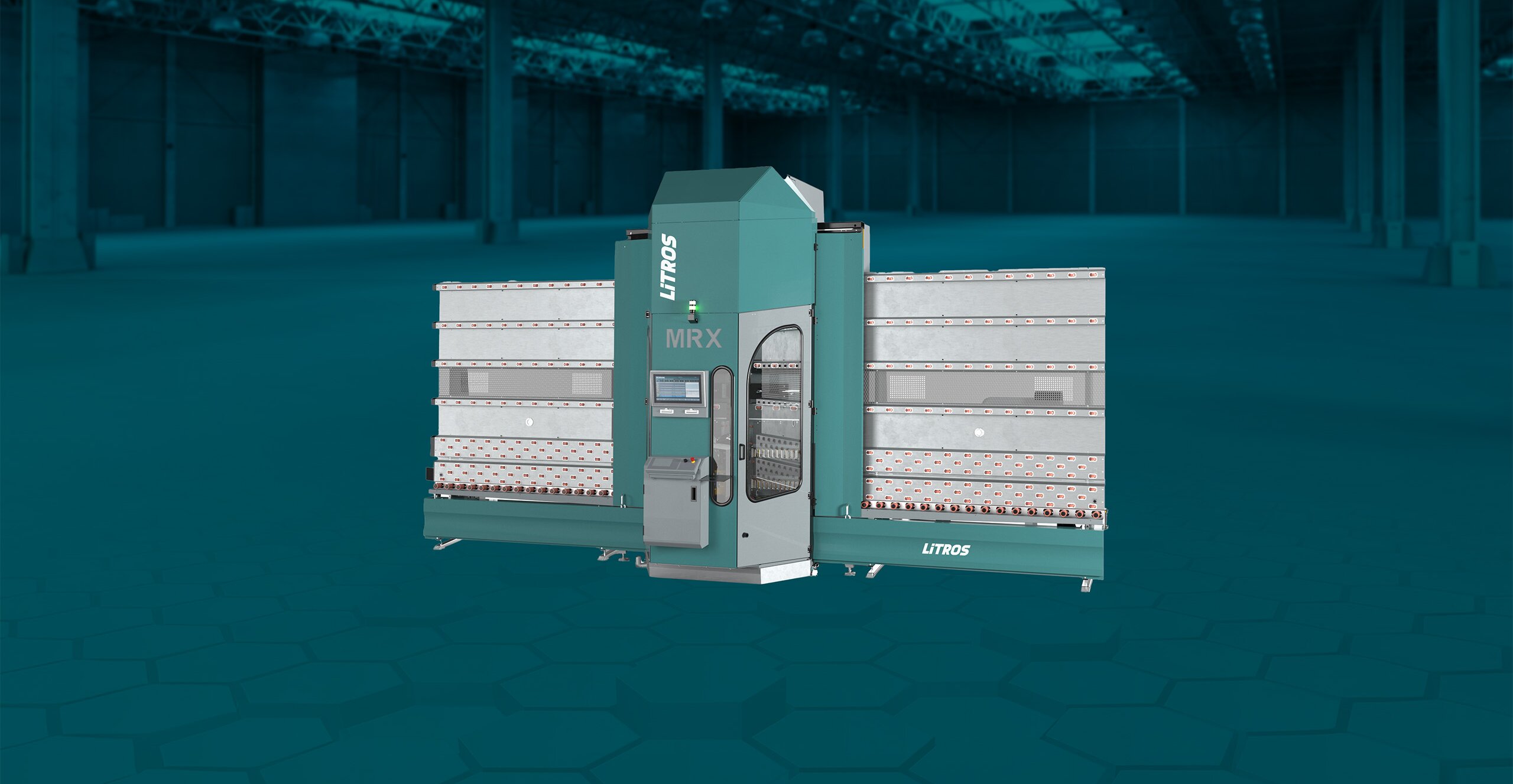

LiTROS Topdrill M-RX G7

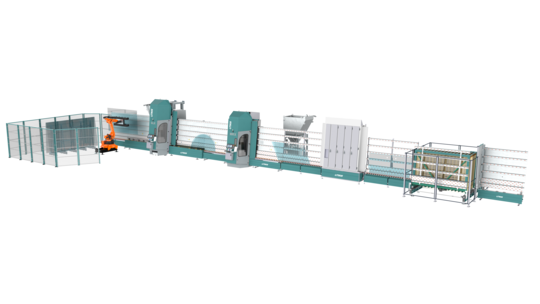

The M-RX is a flexible and fast drilling and milling center for double-sided glass processing — now with the option of an integrated waterjet head. A 10-way tool change head is mounted at the front and rear. During processing, the glass is fixed to the back using vacuum belts. The system impresses with fast cycle times and can be installed as a single machine or in a processing line.

The machine consists of:

Pre-assembled, torsion-free machine frame including main axes and control cabinet

Extension modules

Y-axis drive with ball screws

Automatic central lubrication

Dynamic vacuum belts

Automatic sensors

Optional waterjet head

LiTROS Topdrill M-RX G7

Highlights

01

Intuitive operation for quick start:

The M-RX impresses with its simple and easy handling — ideal for operators with different levels of experience.

Precision through fully automatic CNC control:

Thanks to CNC technology, processing is accurate and fully automated, including measurement of tool length and glass thickness.

Efficient tool change without interruption:

Traveling turret heads allow extremely quick tool changes without the need to release clamping plates — this saves time and increases productivity.

Unrestricted editing of excerpts:

Cut-outs can be made flexibly and without size limits at any point on the glass panel. In the case of particularly large sections, a process with crushing tabs supports manual removal, whereupon the machine automatically continues the program.

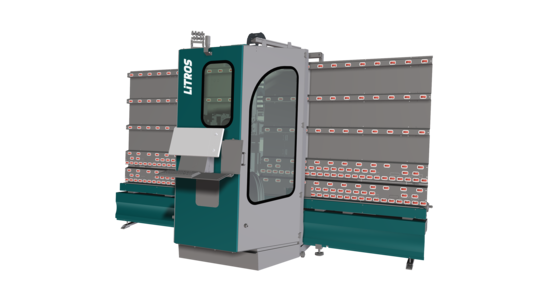

Intelligent vacuum control for a secure fit

24 individually controlled vacuum chambers ensure reliable fixation of the pane — even with special shapes or coated glasses. Existing sections are recognized and the respective chamber is automatically deactivated.

Perfectly coordinated

Function & procedure

01

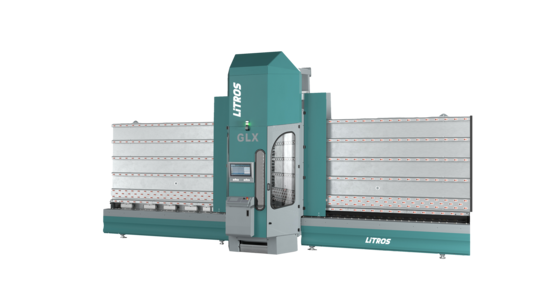

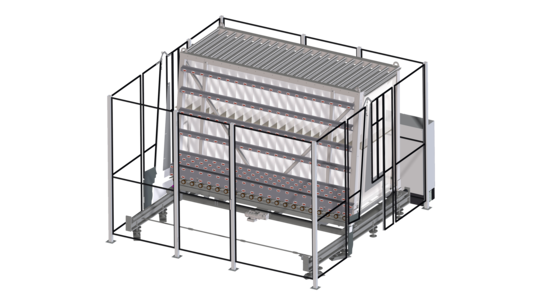

How is the TopDrill M-RX 25 G7 constructed?

The M-RX consists of a sturdy main body with main axes and control cabinet, is about 6200 mm long as standard and contains two extension modules. The running direction is configurable, the Y-axis drive is powered by ball screws, and automatic central lubrication ensures low-maintenance operation. Dynamic vacuum belts allow precise internal processing at any point on the disc. Functions for drill length measurement, glass thickness testing and coating recognition are integrated as standard. Optionally, the system can be equipped with a water jet head, which further improves flexibility and cycle time.

02

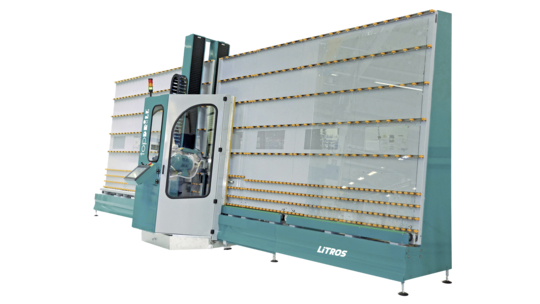

How does the M-RX G7 work?

The M-RX is a fully digital vertical CNC machine for drilling, sinking, milling and grinding flat glass on both sides. Programs can be imported directly on the machine or via interfaces. The processing is carried out precisely in the running direction, which optimizes the cycle time and enables parallel placement. The disc is measured at the inlet; special shapes are possible. Thanks to quick tool changers and high holding power provided by vacuum belts, processing can be carried out flexibly and efficiently — even large cut-outs can be easily made.

03

Who is the M-RX G7 suitable for?

The M-RX G7 is suitable for modern glass processing companies and can be flexibly adjusted thanks to variable processing heights and extension modules. Its compact, vertical design allows installation even when space is limited — even directly on a wall. As a single machine, it enables quick processing of installed glasses, but can be supplemented and extended with grinding or washing machines at any time.

Specifications

LiTROS Topdrill M-RX G7

Here you can find all relevant features of our machine.

contact

Lens height: Open at the top (M-RX 130)/2,600 mm (M-RX 200)

Maximum processing height: 1300 mm (M-RX 130)/2,000 mm (M-RX 200)

Glass thickness: 4 - 20 mm

Minimum dimensions: 600 x 160 mm

Maximum size: approx. 3,200 mm, expandable with extension modules

Transport height: 600 mm

Tilt angle: 7° (+/- 1°)

Max. bore diameter: 80 mm

Spindle speed: 0 — 12,000 rpm

Spindle power: 2 x 5.5 kW

Number of tools: 8 + 8 with Linear 8/10 + 10 with Roto 10

Load: max. 150 kg/linear meter

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?