Description

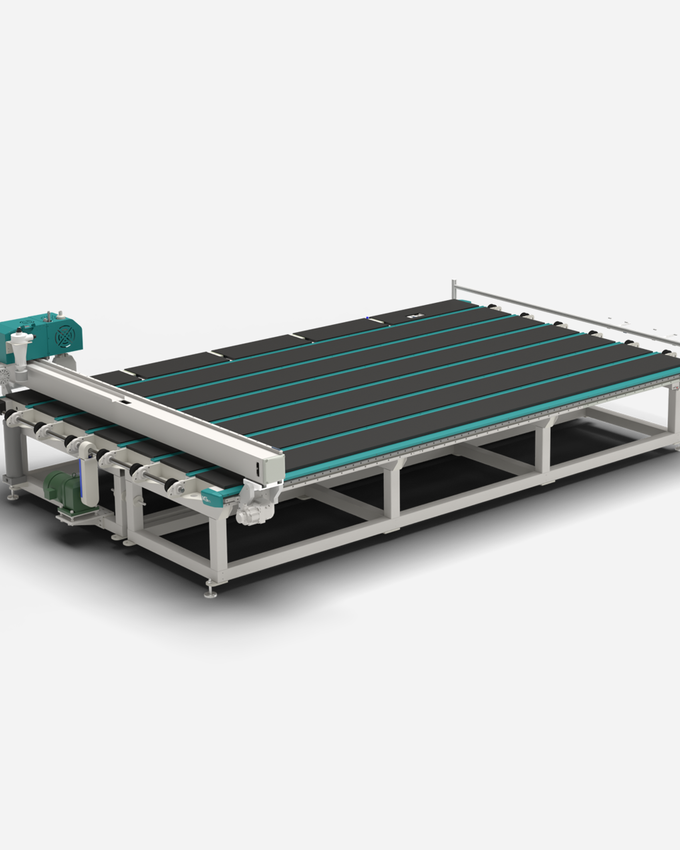

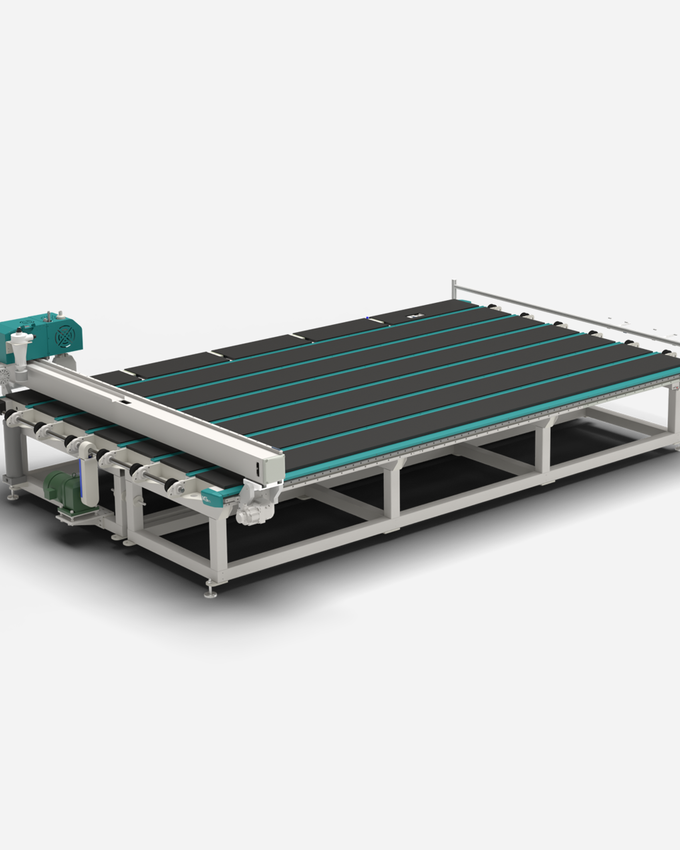

LiTROS Float Cut

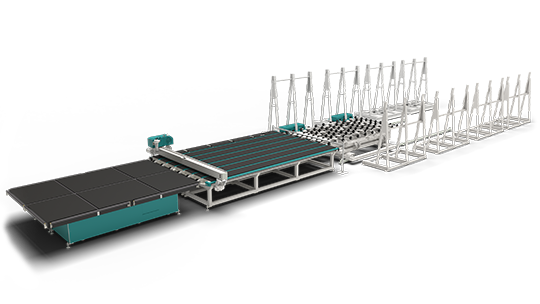

The LiTROS Float Cut is a glass cutting system that was specially developed for cutting and decoating float glass. It enables cutting of glass panes up to a maximum size of 3700 x 2700 or 6000 x 3210 mm.

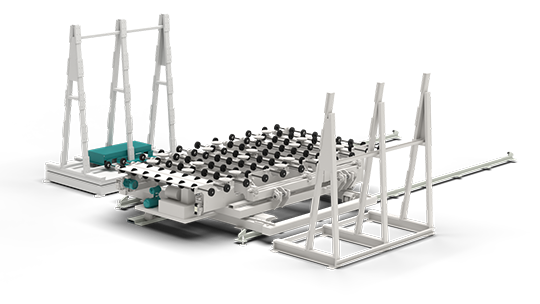

Components of the system

Edge decoating module

Automatic cutting pressure control

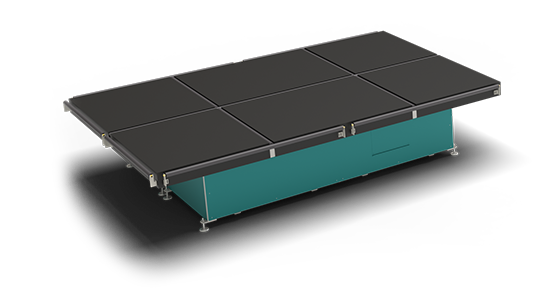

Table top with air cushion

Gantry cutting bridge

Control panel

LiTROS Float Cut

Highlights

01

Edge decoating module

Especially for coating low-e coated glass panes with a grinding wheel.

Automatic cutting pressure regulation

Ensures optimal cutting results by automatically adjusting the cutting pressure.

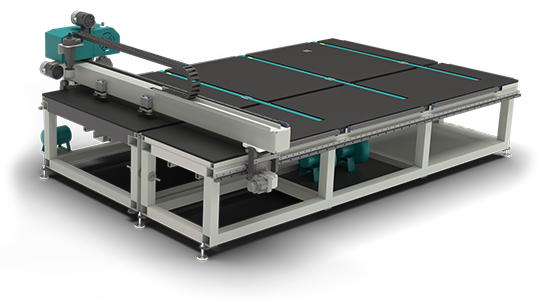

Table surface and cutting bridge

Durable air cushion felt for gentle transport and X-axis gantry drive technology for precise cutting.

Perfectly coordinated

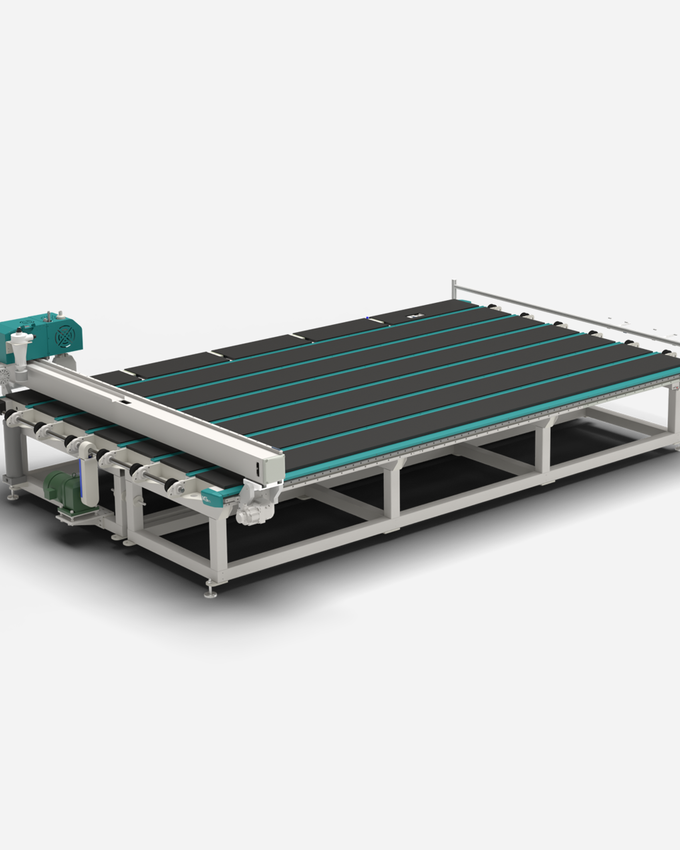

Function & procedure

01

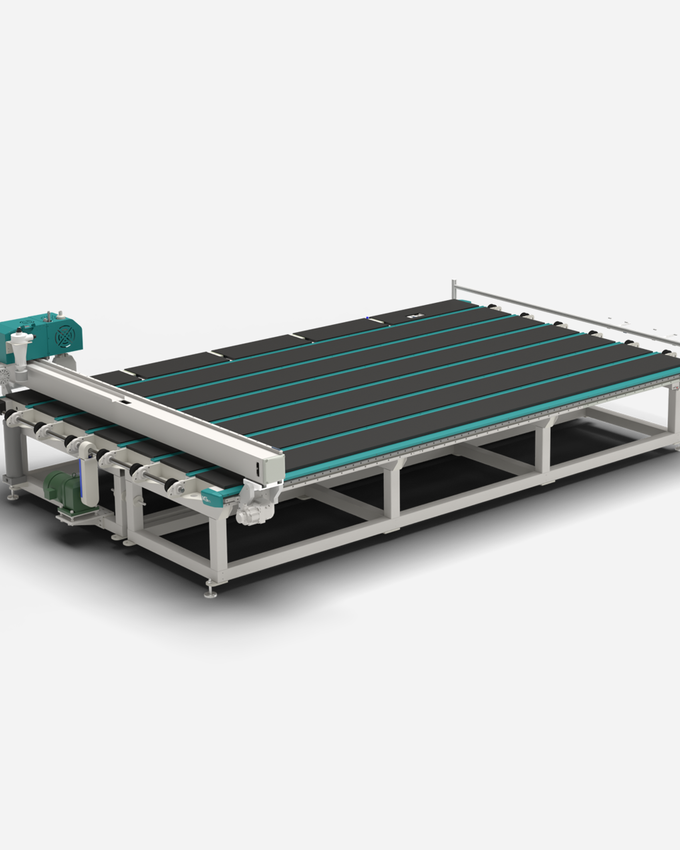

Transport of glass

The glass panes are transported on a table surface equipped with transport belts and air cushions. Automatic transport is possible thanks to the transport belts. The air cushion makes it easy to move the windows and protects them from scratches.

02

Edge decoating

If the glass has a low-e coating, this is removed at the edges with a grinding wheel. An extraction system ensures that the resulting dust is removed.

03

Cutting the glass

The cutting bridge with the cutting head automatically moves over the glass and cuts it according to the specified optimization data. The cutting pressure is adjusted electronically to ensure the best results.

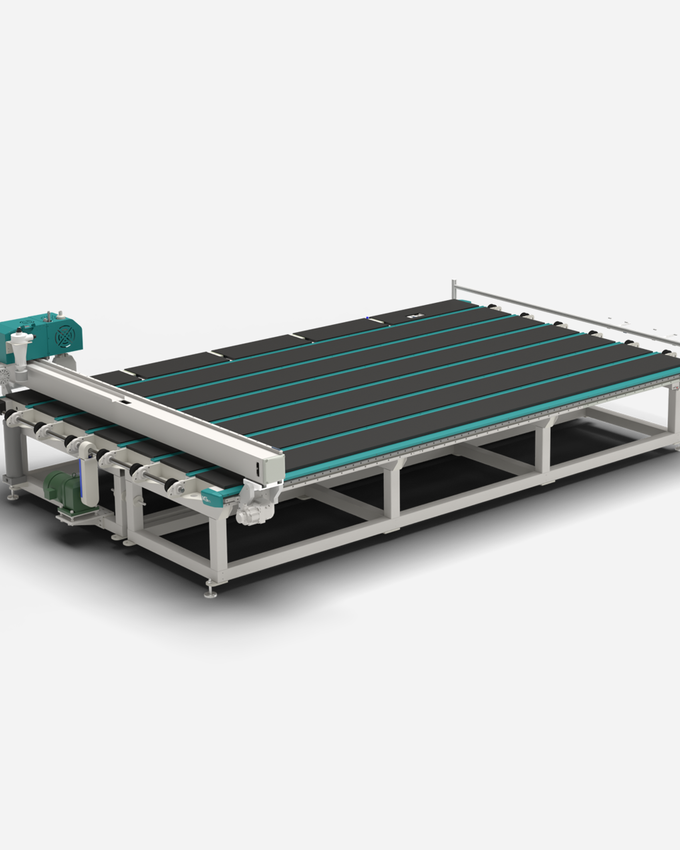

Maximum processing: 3700 x 2700 mm / 6000 x 3210 mm

Automatic cutting: Float glass in X, Y, Z, W and special shapes

Cutting pressure control: Electronic

Cutting speed: 160 m/min

X-axis acceleration: 6 m/sec²

Cutting tolerance: +/- 0.3 mm

Glass thickness: 3 - 19 mm

Edge stripping module: Using a grinding wheel and suction using a vacuum cleaner

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?