Description

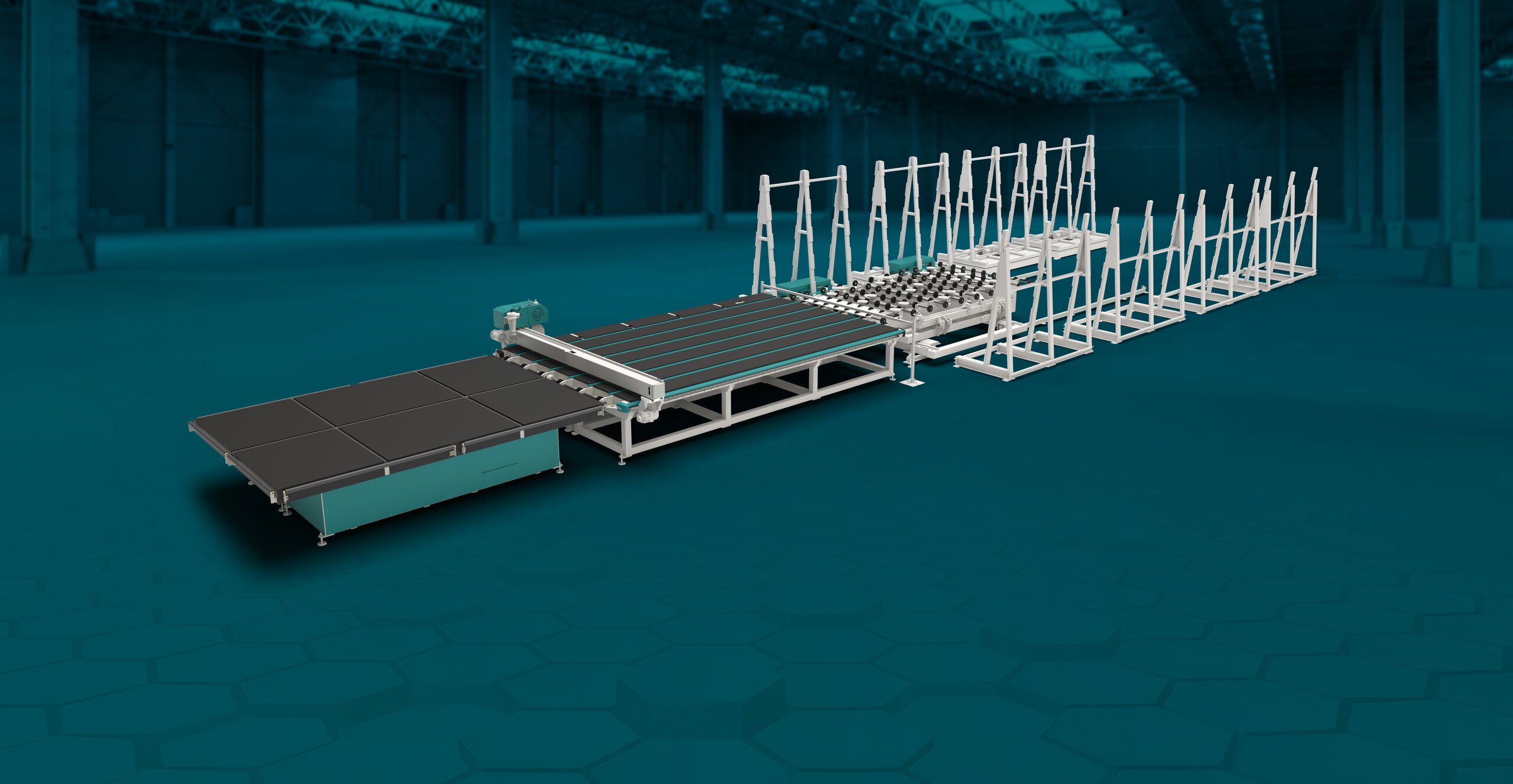

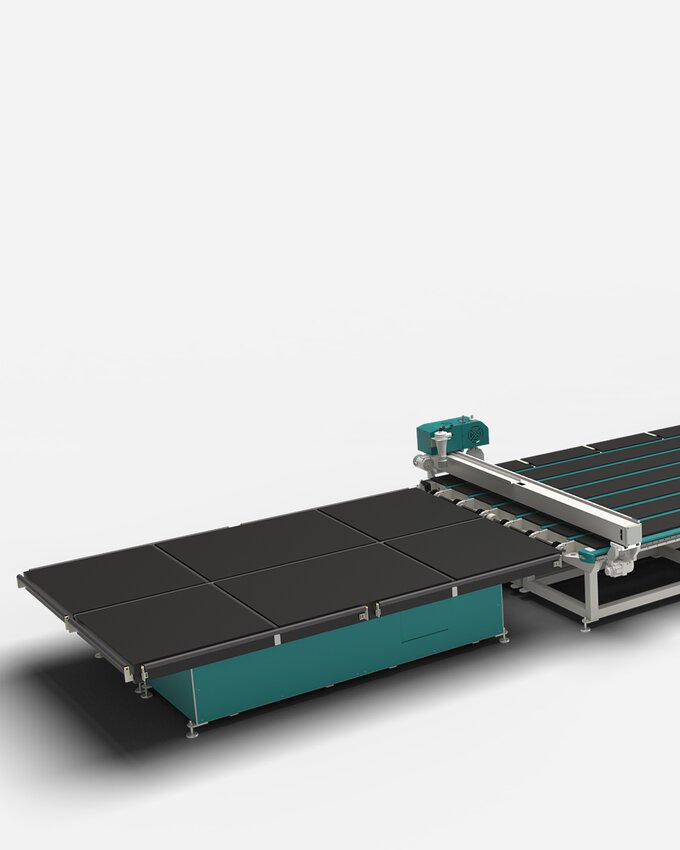

Complete modular solution for float glass cutting

The LiTROS glass cutting line is a sophisticated, modular solution for industrial processing of float glass. It consists of three perfectly coordinated stations: LiTROS Load, LiTROS Float Cut and LiTROS Float break. This line enables a continuous process from loading to cutting up to breaking the glass panes.

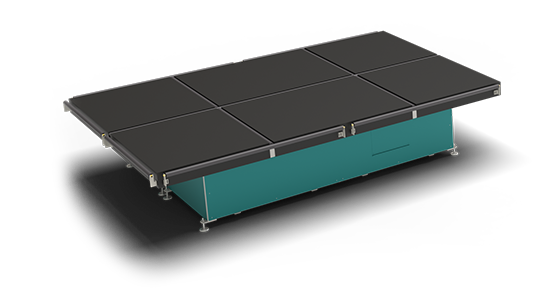

LiTROS Load

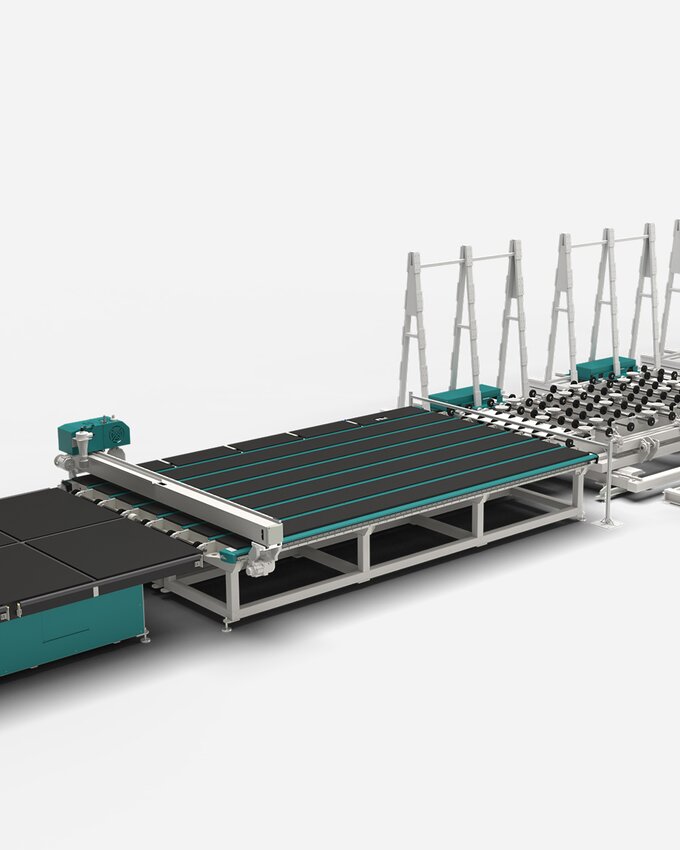

LiTROS Cut

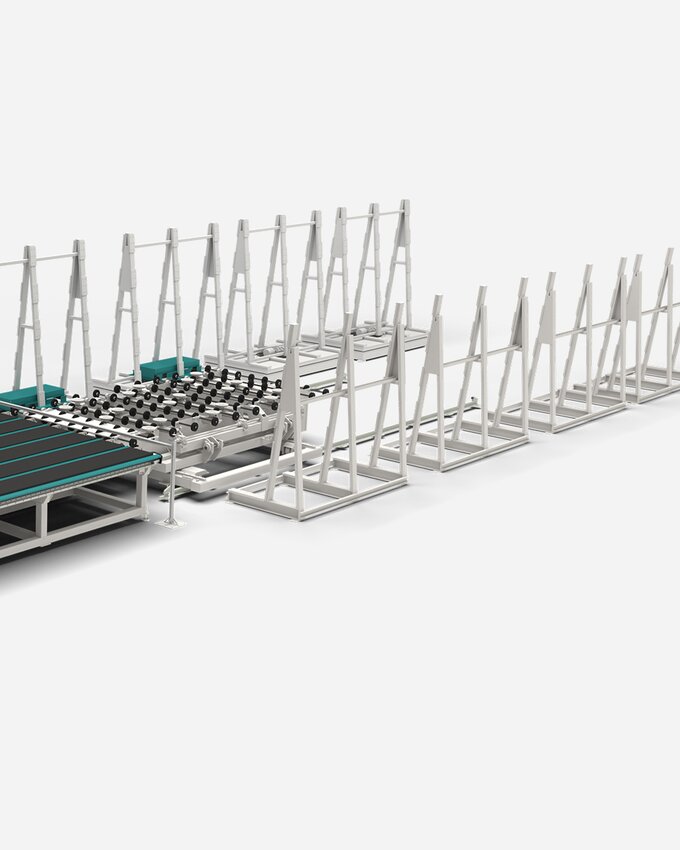

LiTROS Break

LiTROS cutting line

Highlights

01

Continuous process from raw glass removal to finished cutting

The line combines three perfectly coordinated stations load, cut and break and thus enables a seamless process from removal of raw glass panes to precise cutting up to manual breaking.

High flexibility in formats and configurations

The line processes glass panes up to 6000 x 3210 mm and is available in various versions with up to eight racks. This allows you to adapt the line to different production requirements.

Precision and efficiency thanks to modern technology

Automatic cutting pressure regulation, gantry cutting bridge, air cushion table and edge stripping module ensure the highest cutting quality and gentle glass transport — even with coated glass.

Focus on ease of use and safety

The manual crushing station with foot switch, air cushion and crushing strips in the X and Y directions enables safe and ergonomic further processing of the cut panes.

Perfectly coordinated

Sophisticated stations

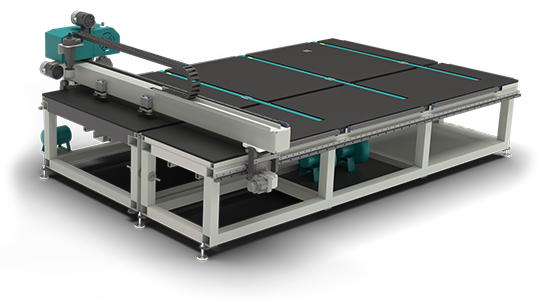

01

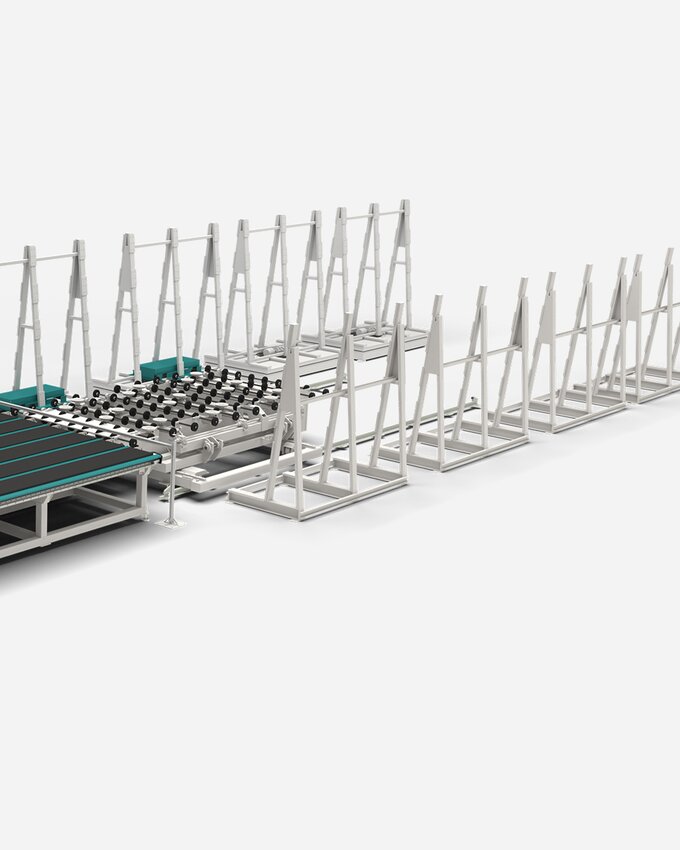

LiTROS Load — glass collection station for raw dimensions

The first step is LiTROS Load to use. This double sided stationary glass removal station was specially developed for removing raw dimensions from L-racks. Depending on the design, it is able to process glass panes of up to 3700 x 2700 mm or 6000 x 3210 mm and can be equipped with two, four, six or eight racks. The raw glass panes are removed from L-racks positioned on both sides. The discs are then loaded onto the line evenly and in a controlled manner. A vacuum pump ensures that the discs are securely fixed during transport. This structured process enables reliable and efficient handling of the raw glass panes and forms the basis for the subsequent processing steps.

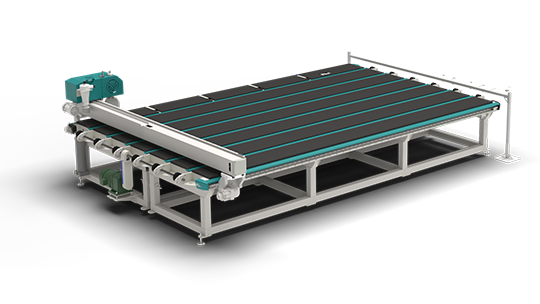

02

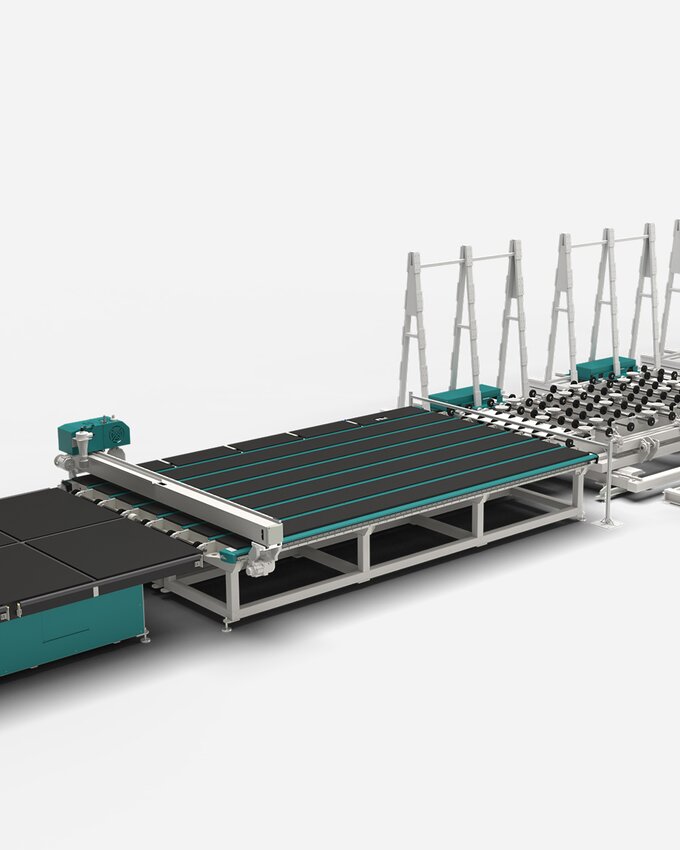

LiTROS Float Cut — glass cutting system for float glass

In the second step, the LiTROS Float Cut the precise cutting of the glass panes. This cutting system was specially developed for cutting and decoating float glass. It processes discs in the same maximum dimensions as the loading station and offers automatic cutting pressure regulation that is optimally adapted to the respective requirements. The cutting bridge with gantry drive, together with the air cushion table surface, ensures gentle and precise transport of the discs during cutting. An integrated edge stripping module also makes it possible to remove Low-E coatings using a grinding wheel.

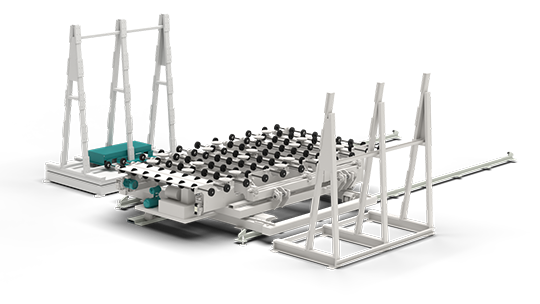

03

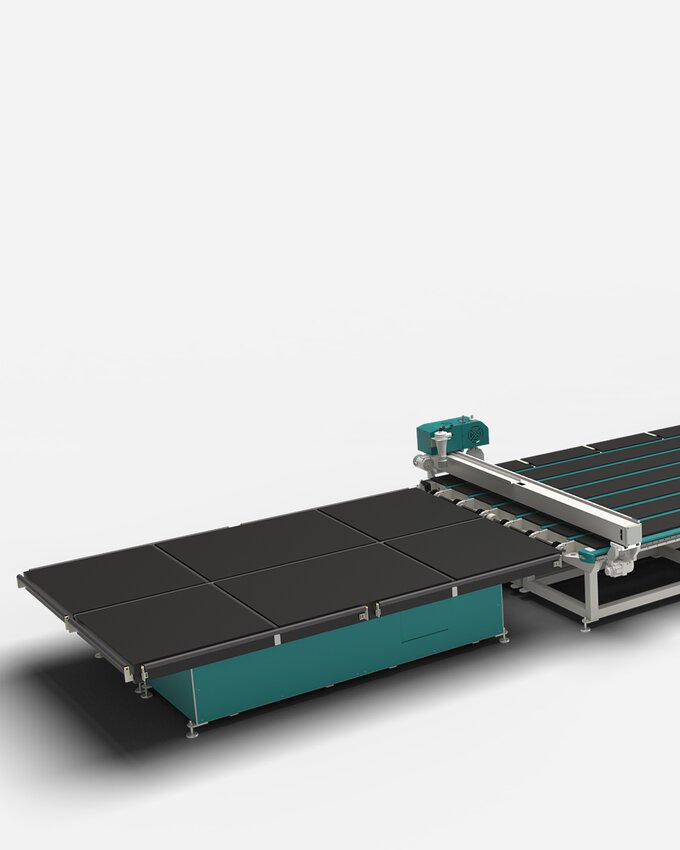

LiTROS Float Break — manually break up sections

The last step is to manually break open the cut glass panes with the LiTROS Float Break. This station is equipped with crowbars in the X and Y directions, which enable precise and controlled breakup. The cut slices are manually inserted into the system and positioned. The breaking process is triggered by pressing a foot button, causing the Y-crushing bar to rise and break open the cut. Further cuts can then be manually broken open. The broken windows can either be transported further manually or gently transported to the next station using the integrated air cushion. Depending on the model, this station is also designed for glass panes of up to 3700 x 2700 mm or 6000 x 3210 mm and a thickness of 3 to 19 mm.

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?