Description

litros:production

litros:production is a software platform for companies in the glass processing industry that want to optimize their entire production chain. It enables the planning and organization of production phases, the creation and management of work batches, integration with specialized machines and full monitoring of the workflow and progress.

Components of system

litros:production

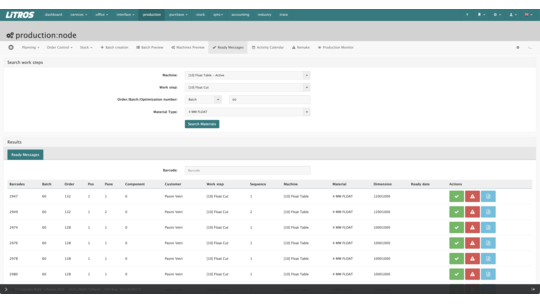

Optional add-ons: litros:scheduling litros:delivery litros:readymessages

litros:office

Highlights

01

Seamless integration with glass processing machines for real-time process control

Intelligent batch creation and cutting optimization to reduce waste and standstill

Full traceability with fault mapping, label printing, and performance reports

Optional add-ons: Software module extensions available upon request

Perfectly coordinated

Functions

01

Production management and cutting optimization (optional add-on required)

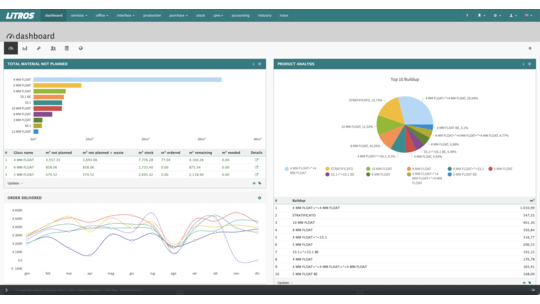

Planning resources across machines and lines with priority settings, multi-location overview with real-time status and KPI alerts, and progress monitoring to identify delays or downtimes.

02

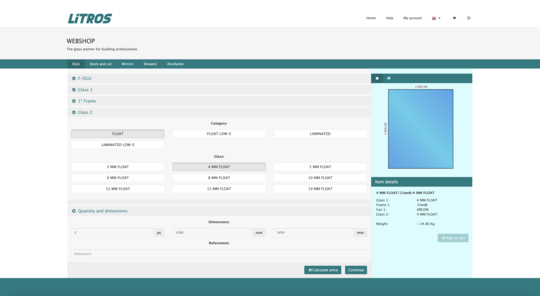

Batch creation

Individual grouping criteria (type of glass, thickness, delivery date, etc.), automatic batch generation from orders or internal requirements, and material availability check during installation.

03

Batch overview

Dashboard with progress, operators and machines, priority management with reorganization and allocation, and work logs including scrap and processing times.

04

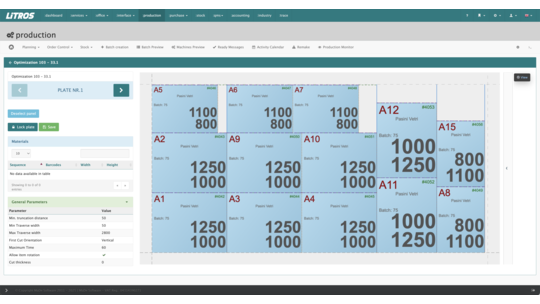

LiTROS Cutting optimization

Nesting algorithms to minimize waste, bidirectional communication with LiTROS machines, and management of multiple disk formats including leftovers.

05

Bug management

Manual or visual fault mapping (scratches, bubbles, etc.), automatic recalculation of cutting patterns to avoid errors, and statistical reports on error types and frequency.

06

Glass thickness management

Definition of tolerances per product for multi-layer or laminated glass and automatic compensation for bearing thickness deviations.

07

optimization editor

Graphical interface for manual layout adjustments, multiple simulations to compare strategies, and save and reuse individual cutting configurations.

08

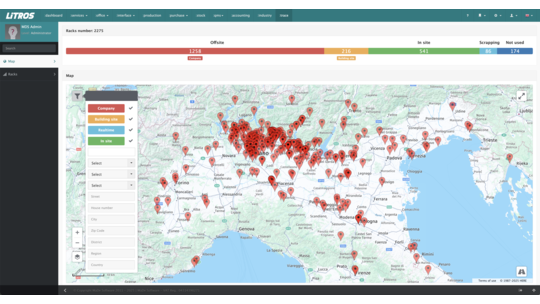

Rack optimization for delivery

Rack allocation based on plate dimensions and load plans, optimized loading/unloading processes for customer delivery, and tracking rack availability in storage and transportation.

09

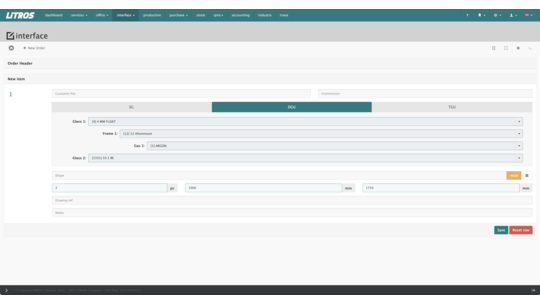

Bending machine interface

Transmission of bending parameters (radius, angle, thickness) to machines, compliance tests against planned specifications and full traceability of curved batches, including quality control.

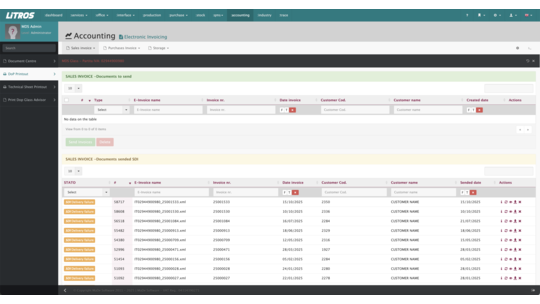

10

Label printing

Barcode and QR code labels with batch and part information, customizable formats in accordance with internal standards, and automatic printing when production starts.

11

Production reports (optional add-on required)

Detailed analyses of productivity, waste, errors, and operator performance, exportable reports for financial and management purposes, and decision-making tools for workload distribution and maintenance planning.

12

Machine reports (optional add-on required)

Machine-specific reports (drilling, edging, washing), preventive maintenance planning based on usage data and historical performance logs for investment decisions.

13

Packaging management (optional add-on required)

Packing lists with item information, weight and volume, suggestions for protective materials based on product specifications, and integration with logistics and carriers for shipping preparation.

14

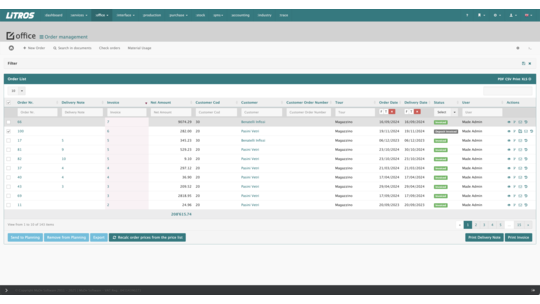

Order status overview

Dashboard for active orders with filters and alerts, tracking production readiness and material availability, and notifications in case of delays or bottlenecks.

15

Material delivery monitoring

Tracking of incoming deliveries and expected arrival times, automatic inventory update upon receipt of goods and prevention of downtimes due to lack of materials.

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?