description

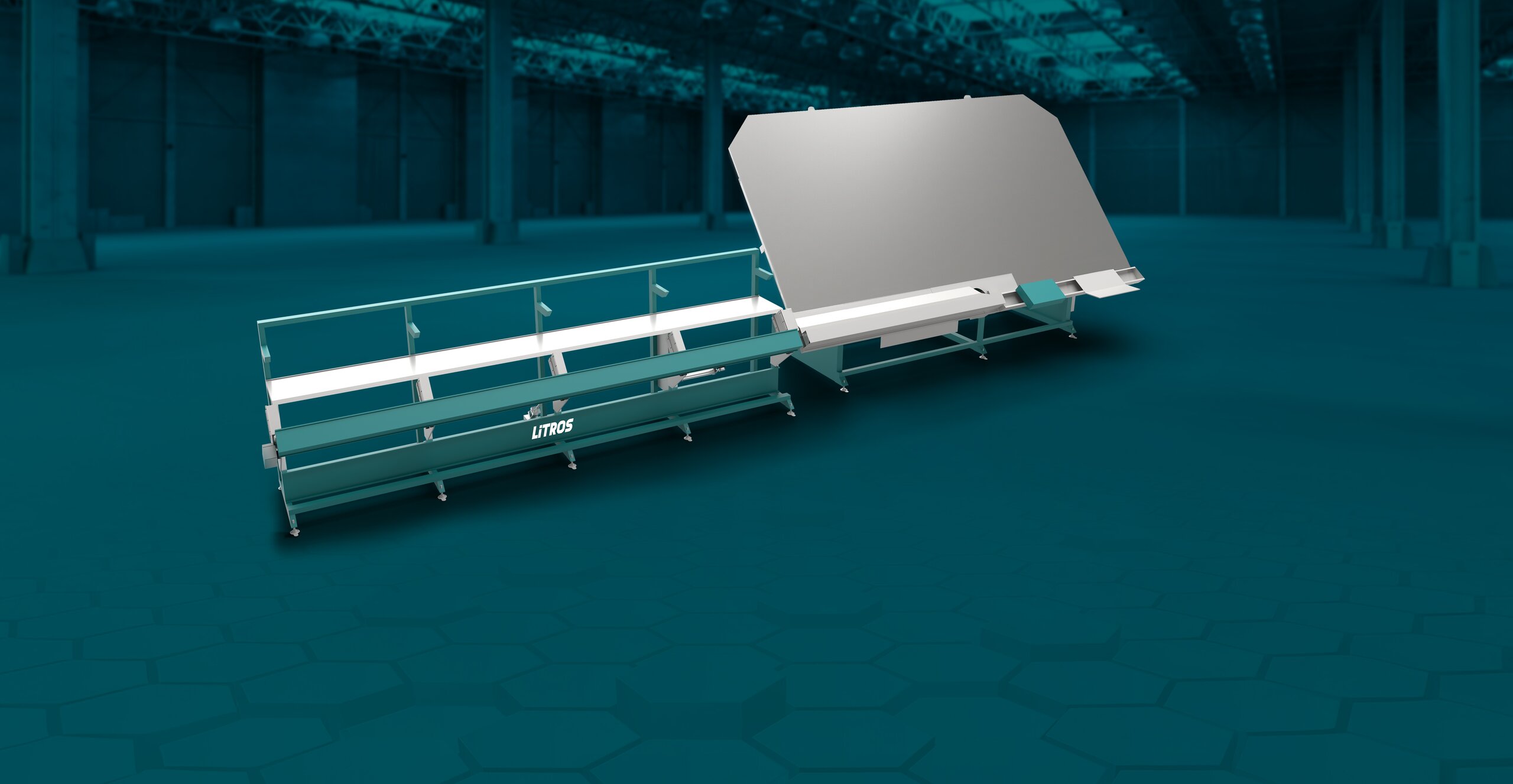

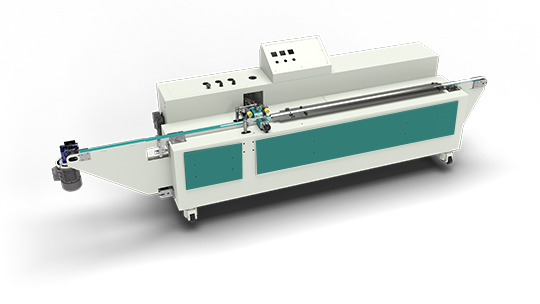

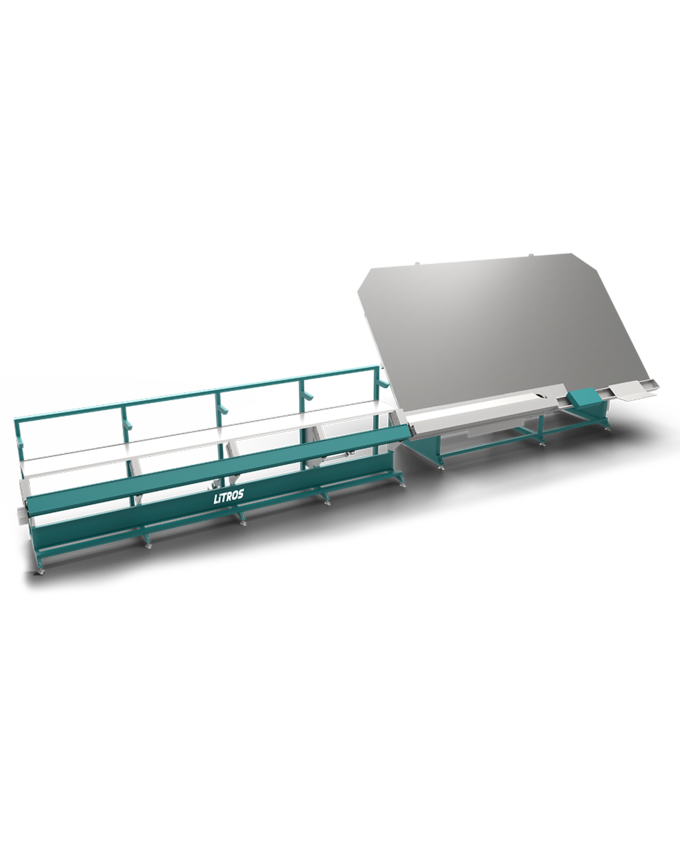

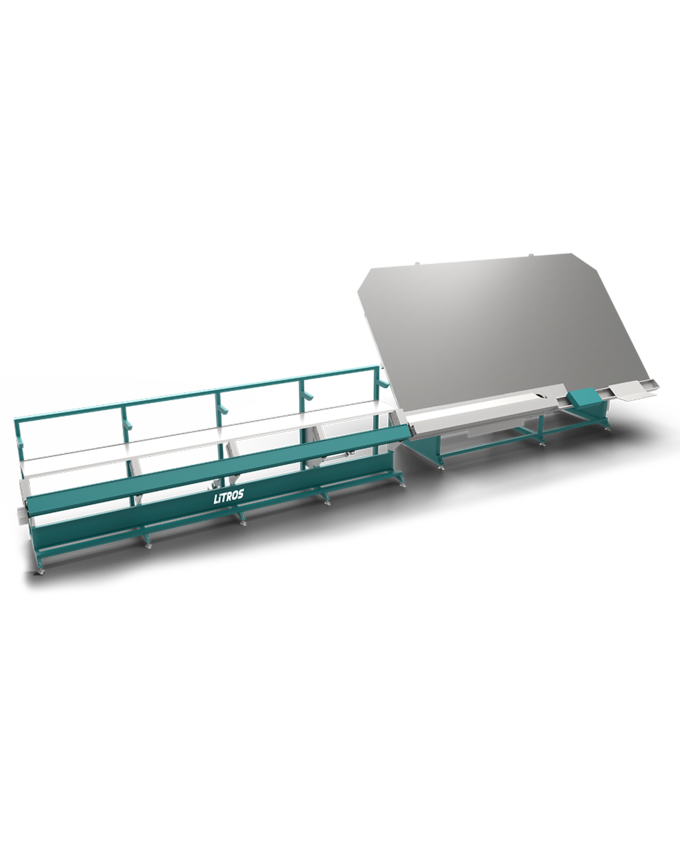

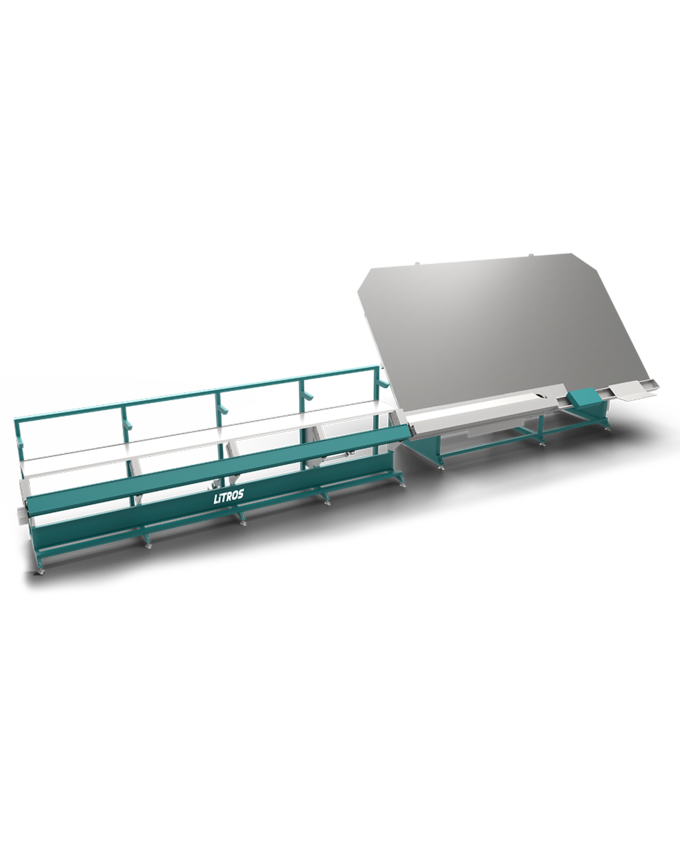

LiTROS IG Bend

LiTROS IG Bend It is a fully automatic bending system for producing precise aluminum and stainless steel spacer frame profiles. system This makes it possible to process various profile widths and produces one-piece or two-piece frame pieces with maximum repeatability.

machine It consists of:

Three magazine slots with automatic profile bar feed

Clamping device for weight optimization

Guiding and clamping device for spacer and corner connector

Bending unit with top/bottom clamping

Finger clamping for uniform bending quality

Servo drive to adjust the bending angle

Automatic speed control

Touch screen control panel

Automatic and manual operation

Ethernet connection for work orders and status queries

Integrated self-diagnosis

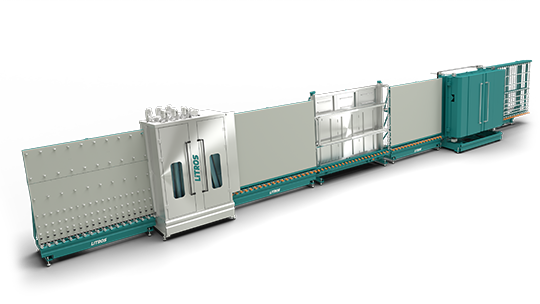

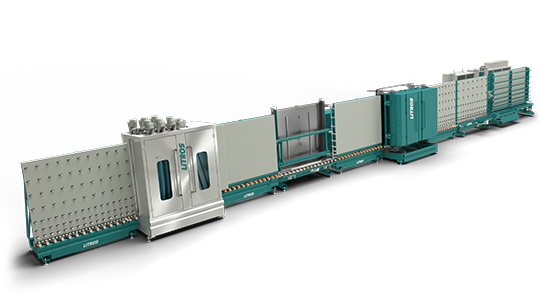

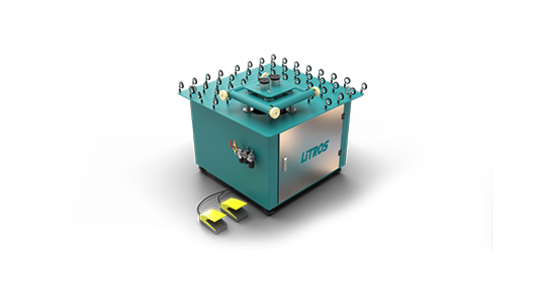

LiTROS Insulating Stand Alone

highlights

01

Precise bending quality:

Exact frame geometry thanks to precision servo control and constant clamping technology.

Automatic profile feed:

The profile bars are fed fully automatically from the 3-compartment magazine — ideal for continuous production.

Constant profile thickness:

Top, bottom and finger clamps ensure consistent results with different types of spacers.

Flexible processing:

Suitable for all standard spacer widths (5-24 mm) as well as aluminum and stainless steel — without additional conversion.

User-friendly operation:

Touch screen control with automatic and manual operation for intuitive, easy handling.

High production capacity:

Short cycle times and automated processes enable up to 1400 frame in 8 hours.

Compact & cost-effective:

No automatic measurement or storage system is required.

Minimal investment and operating costs thanks to simple design.

Perfectly coordinated

Function & procedure

01

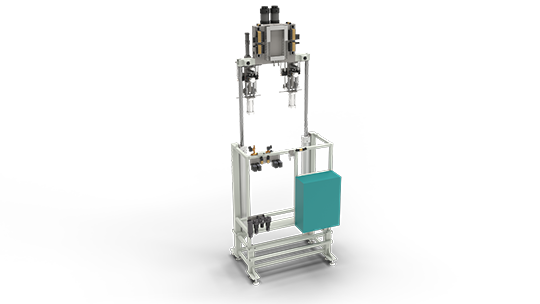

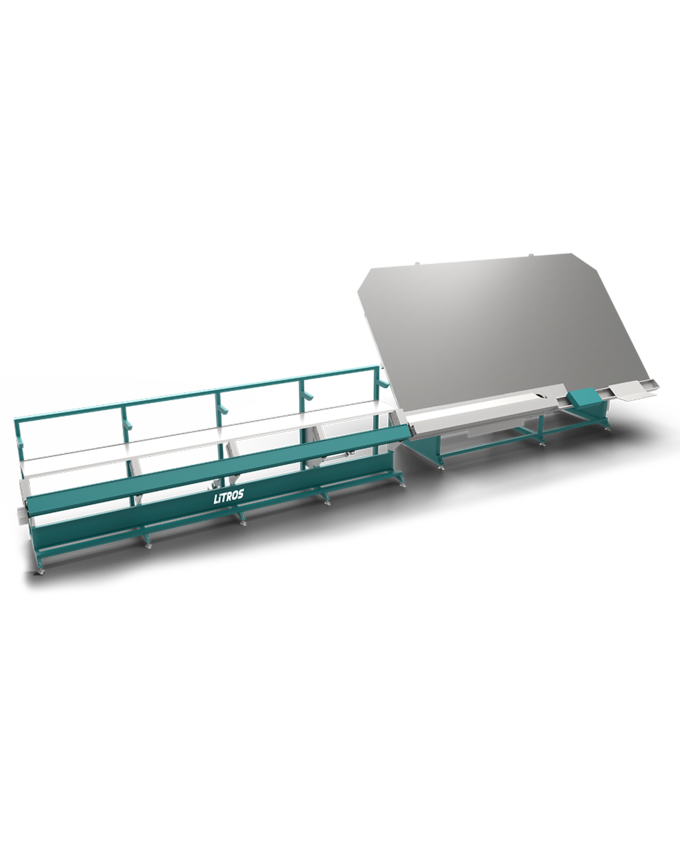

Positioning and bending

The bending unit fixes the profile using upper, lower and finger clamps. The digital servo drive shapes the corners exactly according to the specifications. The speed automatically adapts to profile type and size.

02

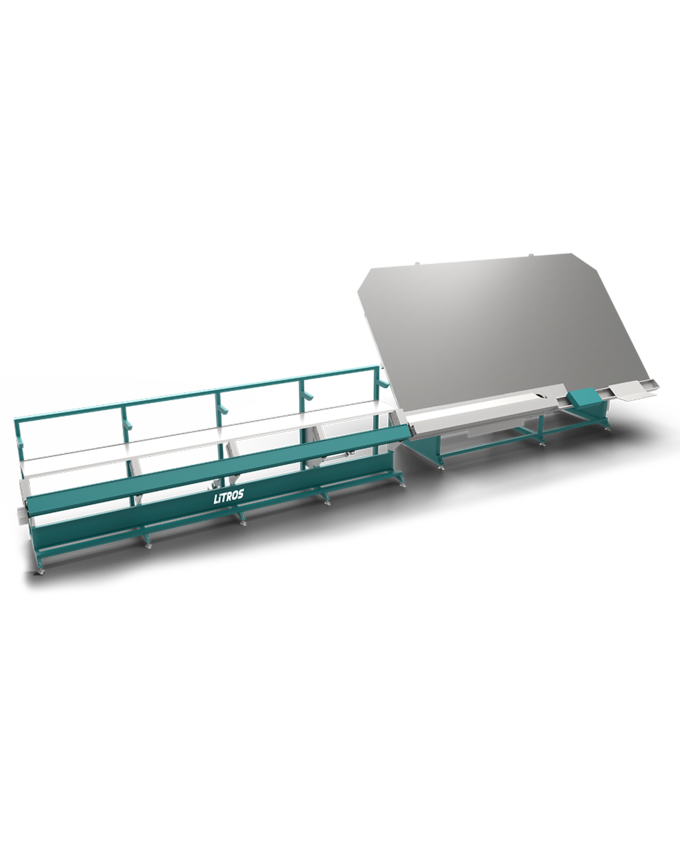

frame manufacturing

Depending on the model, the frame one or two pieces are bent to the desired size. The precise clamping technology ensures constant profile thicknesses and exact angles.

03

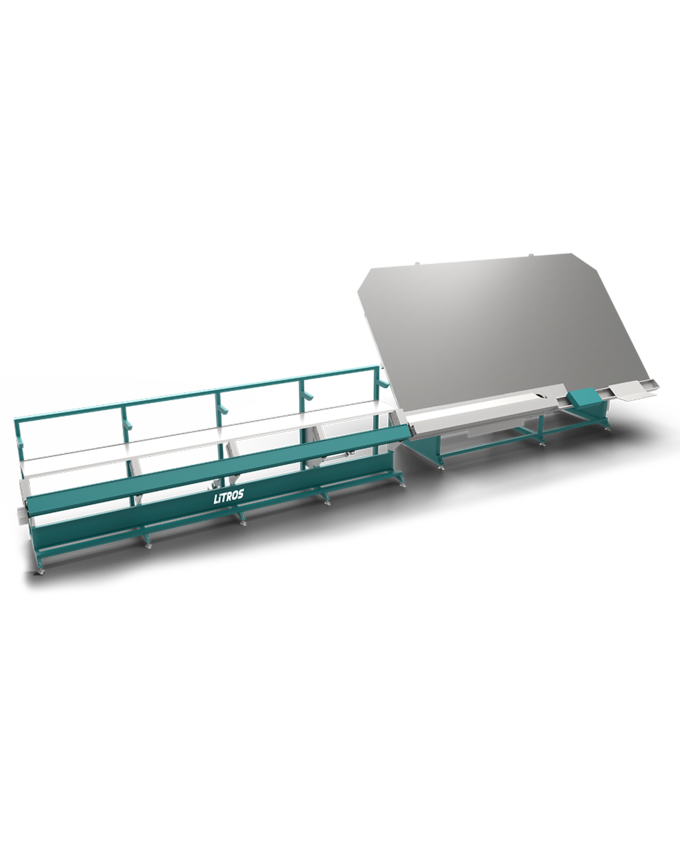

removal

The finished one frame is removed manually or handed over to the next station.

specifications

LiTROS IG Bend

Here you can find all relevant features of our machine.

Max. frame size (mm): 2500 × 2500 (1 piece)/3100 × 4000 (2 pieces)

Min. frame size (mm): 250 × 250

Spacer width (mm): 5 — 24

Transport speed (m/min): 100

Bending accuracy (mm): ±0.5

Working height (mm): 950

Spacer types: aluminum, stainless steel

Capacity: 1400 frame (1000 × 1000 mm) in 8 h

Cycle time: 15-16 seconds (1000 × 1000 mm)

Electrical design: 3P 380—480 V, 50/60 Hz, 15 kW

Compressed air (kg/cm²): 6

Magazine places: 3

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?