Description

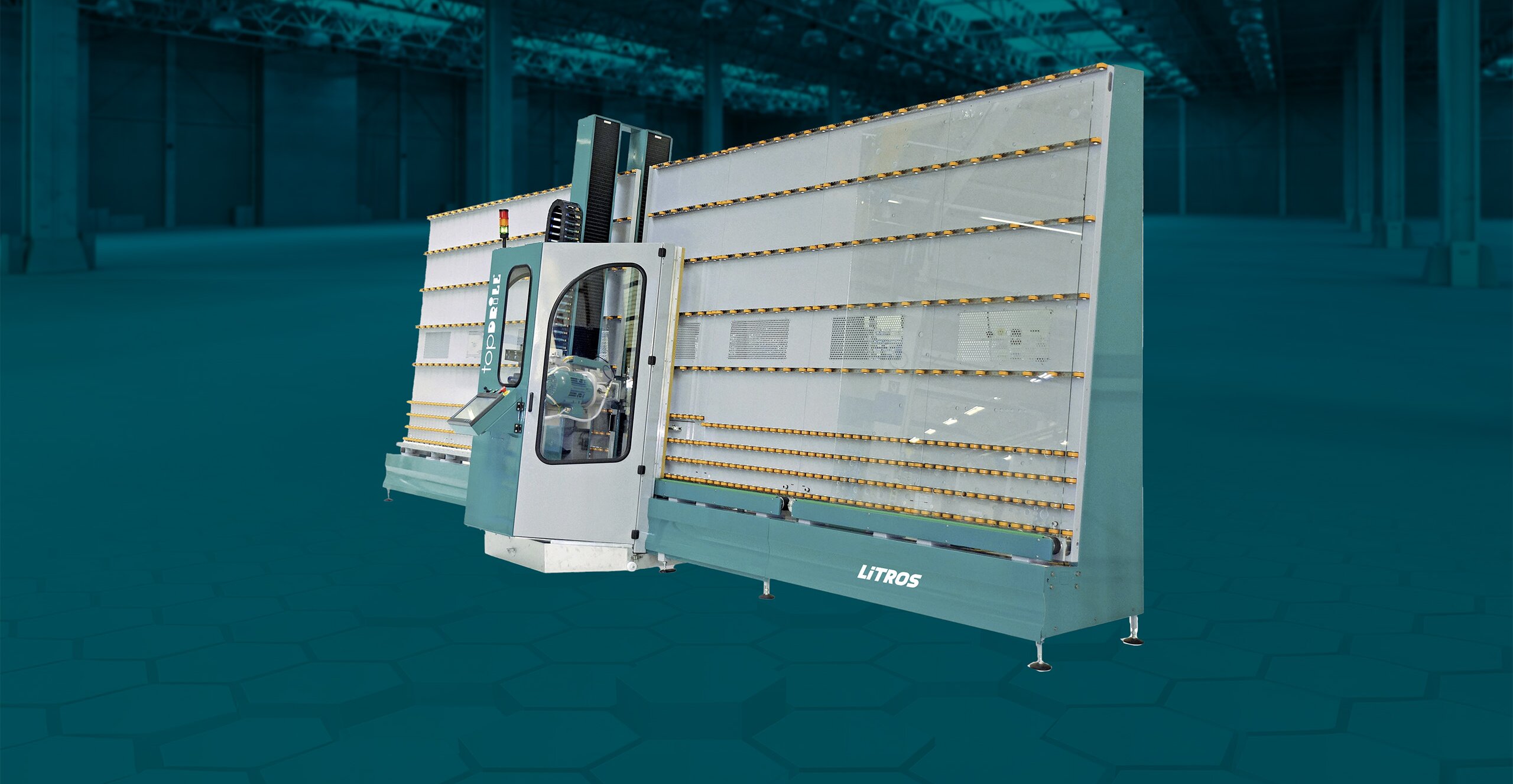

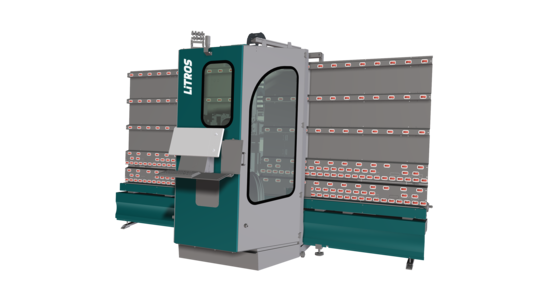

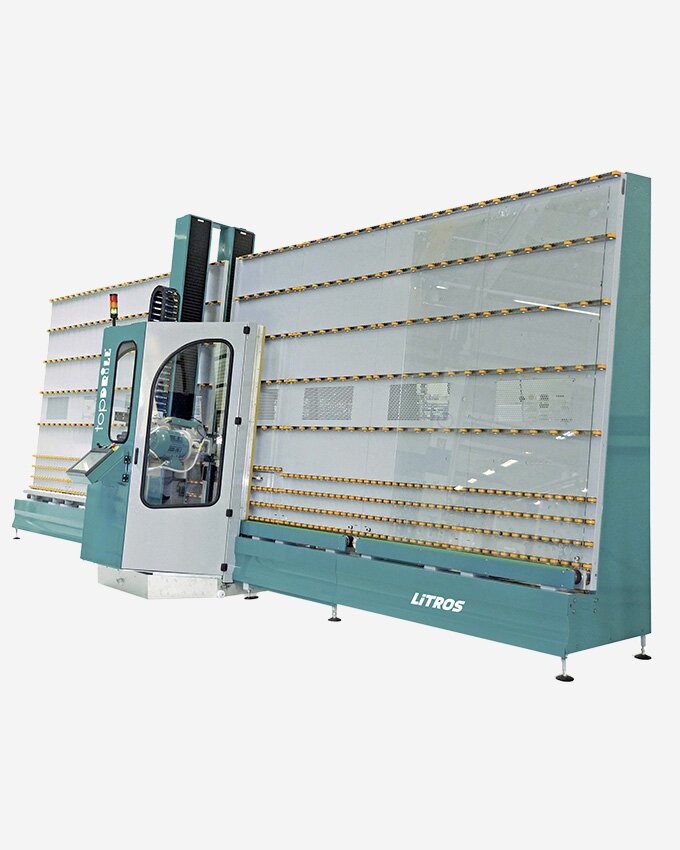

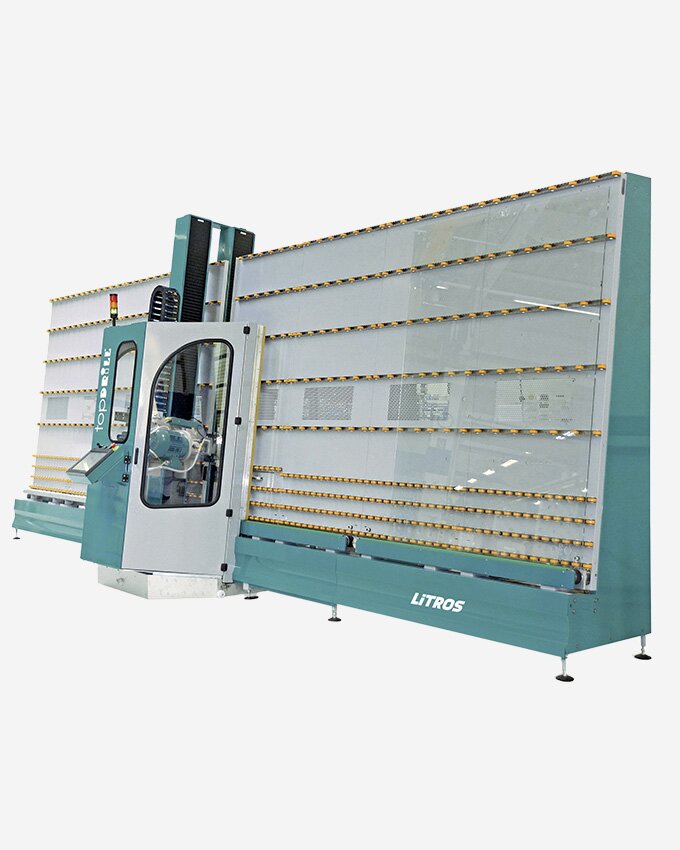

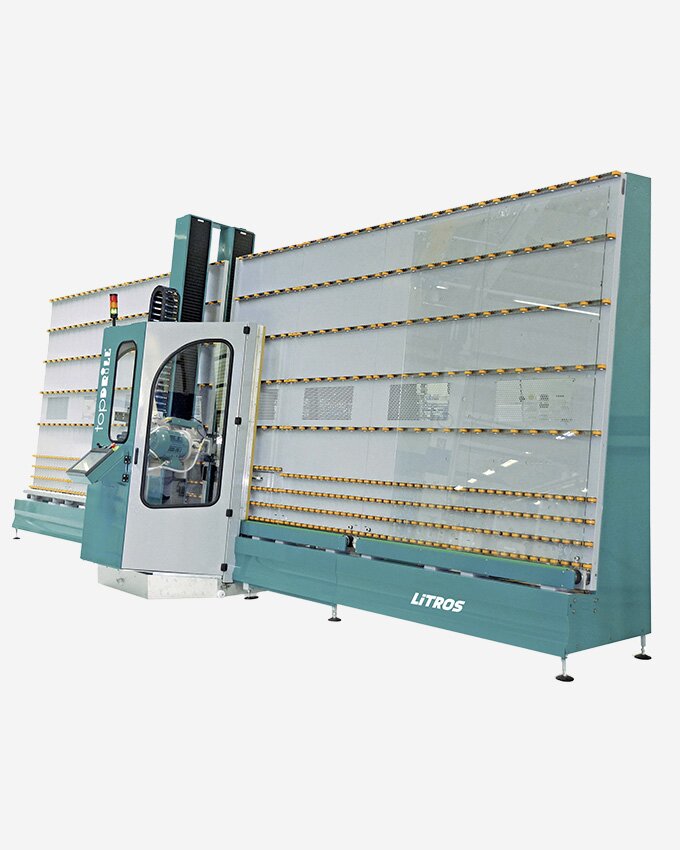

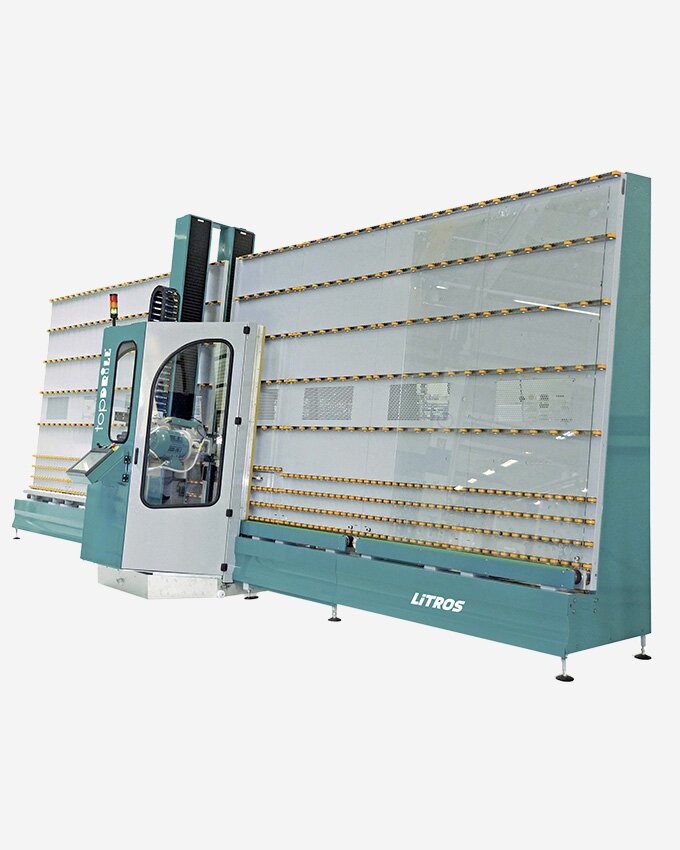

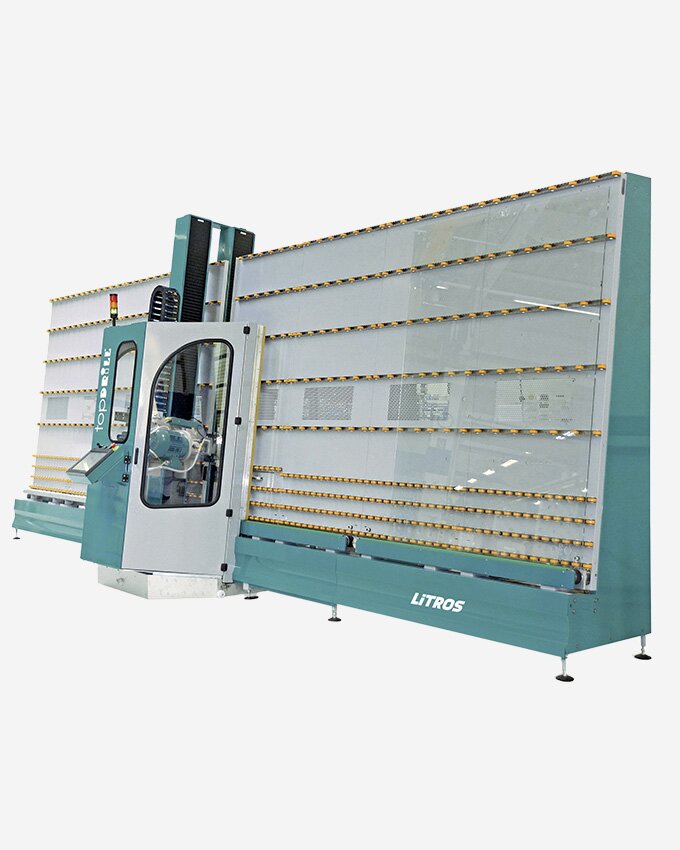

LiTROS Topdrill NC G8

The LiTROS Topdrill NC G8 is comparatively compact. The configuration can be adapted as required. The machine is ideal for drilling individual pieces or series with the same drilling diameters. In conjunction with the optional waterjet head, surface and edge sections can also be created very economically.

The LiTROS Topdrill NC G8 can be installed as a single device or as part of the Combifin line. It can be extended at any time with a Topclear washing machine.

The machine is available in two versions:

- LiTROS Topdrill NC 14 G8

- LiTROS Topdrill NC 25 G8

The machine consists of:

Massive base frame (G8 series)

Flexibly combinable drill heads

Extension modules

Side maintenance accesses

Model NC 14: Open-facing design

Model NC 25: Closed at the top

LiTROS Topdrill NC G8

Highlights

01

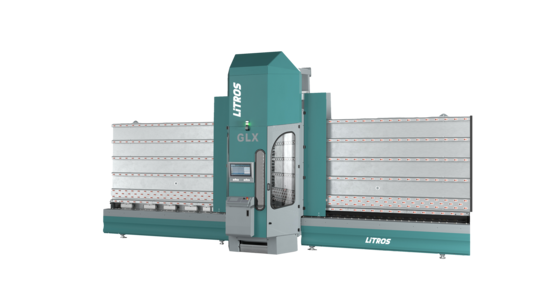

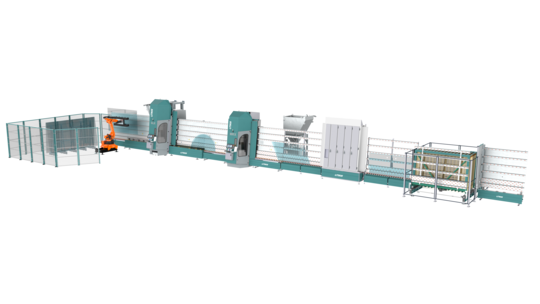

Can be used flexibly — as a single device or in line

Whether as a stand-alone solution or integrated into a Combifin line with GLX and Topclear — the machine adapts to any production environment.

Industry 4.0 ready and easy to operate

Thanks to intuitive control and digital interfaces, the system is future-proof and particularly user-friendly.

Fast cycle times with consistent quality

The machine works efficiently — even with changing drilling diameters — and ensures a consistently high processing speed.

Maximum versatility thanks to waterjet option

With the optional water jet head, even complex cutouts and holes in variable diameters can be precisely implemented.

Accurate and reliable

Function & procedure

01

How is the Topdrill NC G8 constructed?

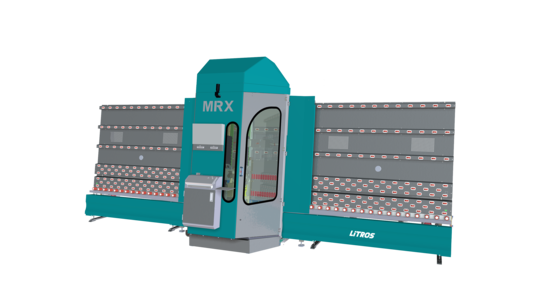

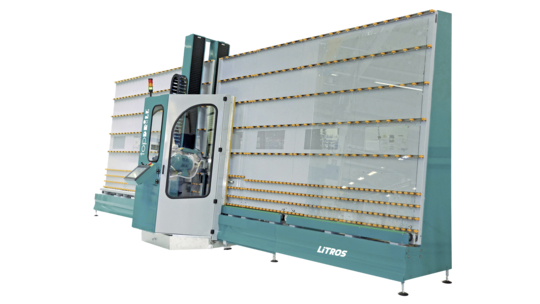

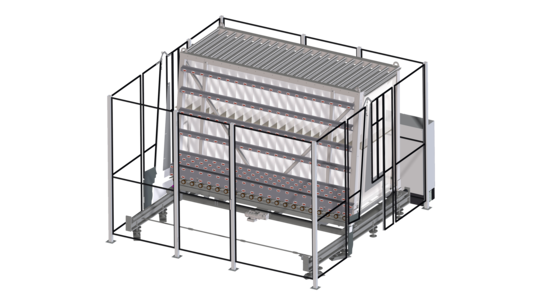

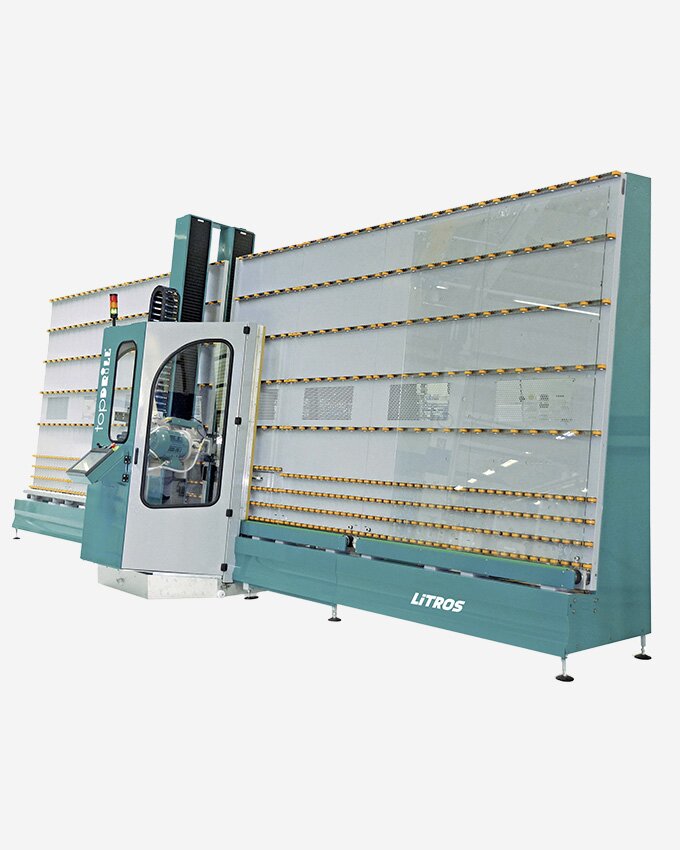

The Topdrill NC G8 is based on the solid base frame of the G8 series and offers flexible combinations of heights, drill heads and overall lengths. Since the design of the NC 14 is open at the top, higher glasses can also be processed while respecting the maximum dimensions. The design of the NC 25 is closed at the top. However, the maximum height of the glasses used can be 200 mm higher than the maximum processing height. If the NC system is installed as a single machine, the system can be mounted directly on a rear wall to save space. Maintenance access is always possible from the side. Extension modules make it possible to adapt to different lengths of glass, and the machine can be extended to a line at any time with GLX grinding machines or TopClear washing systems. The running direction is freely selectable.

02

How does the Topdrill NC G8 work?

The Topdrill NC G8 is a vertical CNC drilling machine for double-sided drilling of flat glass, with optional waterjet cutting and manual quick change. It offers flexible data entry, automatic glass measurement and recognizes special shapes. The drilling process is fully automated; with multiple diameters, the machine starts with the smallest. With the optional CMX system, drills can be changed on both sides in seconds. Cut-outs of any type are possible — ideal for applications such as shower or all-glass doors.

03

Who is the Topdrill NC G8 suitable for?

The Topdrill NC G8 is suitable for any modern glass processing company with uniform processing procedures. With the available extension modules, the system or the maximum glass length can be adapted to requirements. Due to their vertical design and very compact design, the G8 machines can be installed in tight spaces. Thanks to the side maintenance accesses, the machine can be installed directly on a wall. The option to expand with additional modules or further processing devices provides investment security.

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?