Description

litros:trace

With it, you can litros:trace keep an eye on delivery locations at all times — from factory preparation to allocation and return. Through the optional integration of innovative technologies such as RFID and geolocation (Sigfox/LoRa), the system enables precise real-time control, reduces losses and optimizes the entire logistics process.

The result: more transparency, faster processes and noticeable cost and time savings.

Core modules and features:

Centralized rack management

Map tracking and route planning

Table view and advanced analytics

RFID add-on

Geolocalization add-on

Scheduling and automated notifications

litros:trace

Highlights

01

Tracking:

Real-time tracking of delivery locations via RFID and geolocation.

Automated allocation:

Automatic allocation of delivery notes and complete history of frame status.

Smart notifications:

Smart alerts and scheduled reports for overdue or missing racks.

Real-time tracking and intelligent management of delivery points

Function & procedure

01

Centralized rack management

Delivery points are automatically assigned to the appropriate delivery notes, which significantly reduces manual effort and errors. Each rack receives a digital ID that completely documents all movements such as check-in and check-out as well as references to delivery notes and departure times.

02

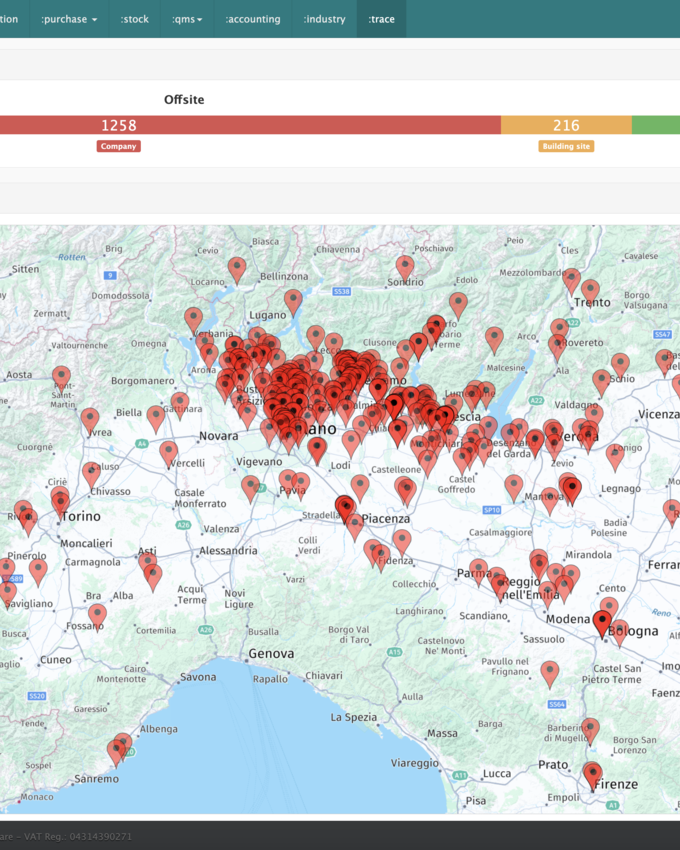

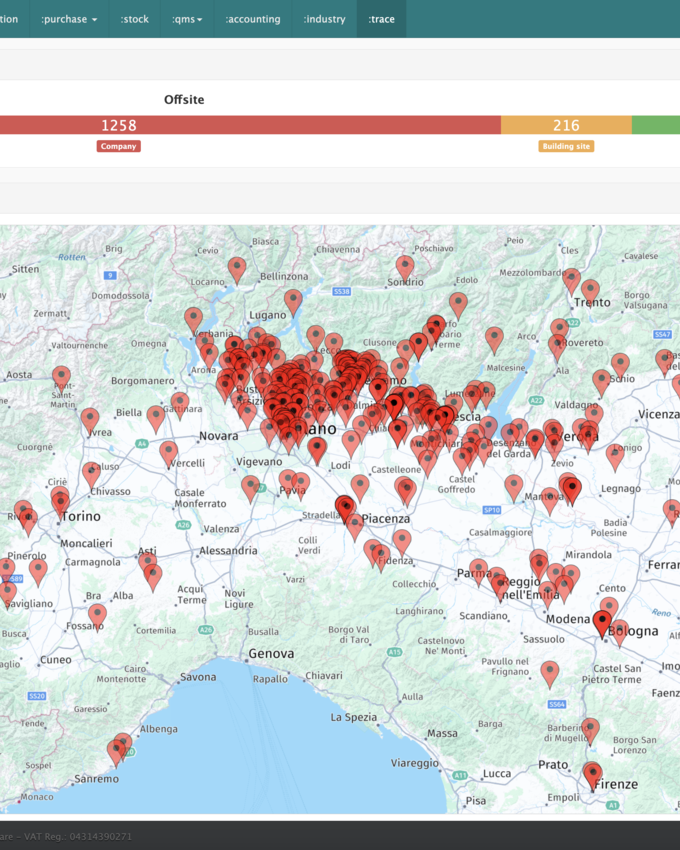

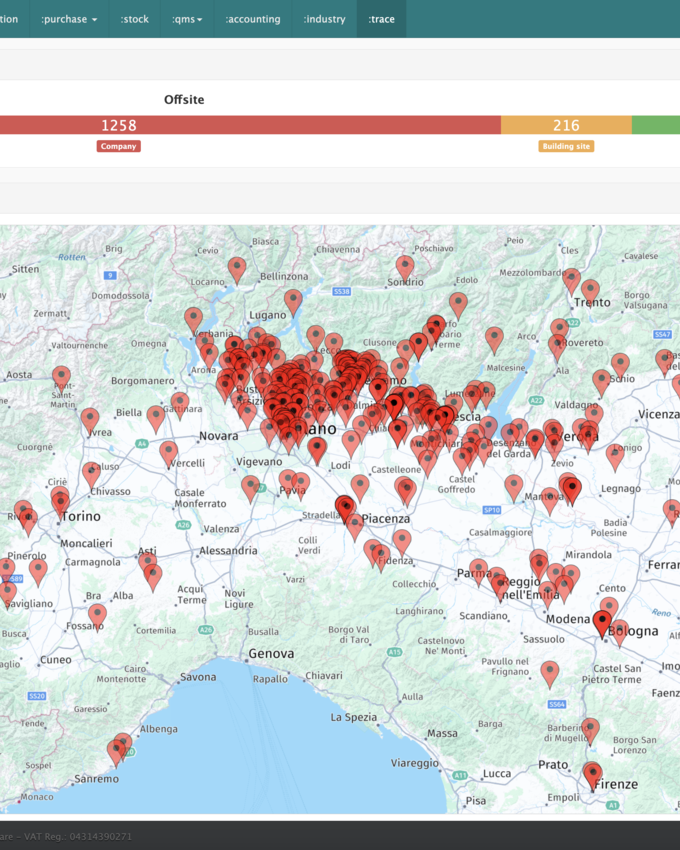

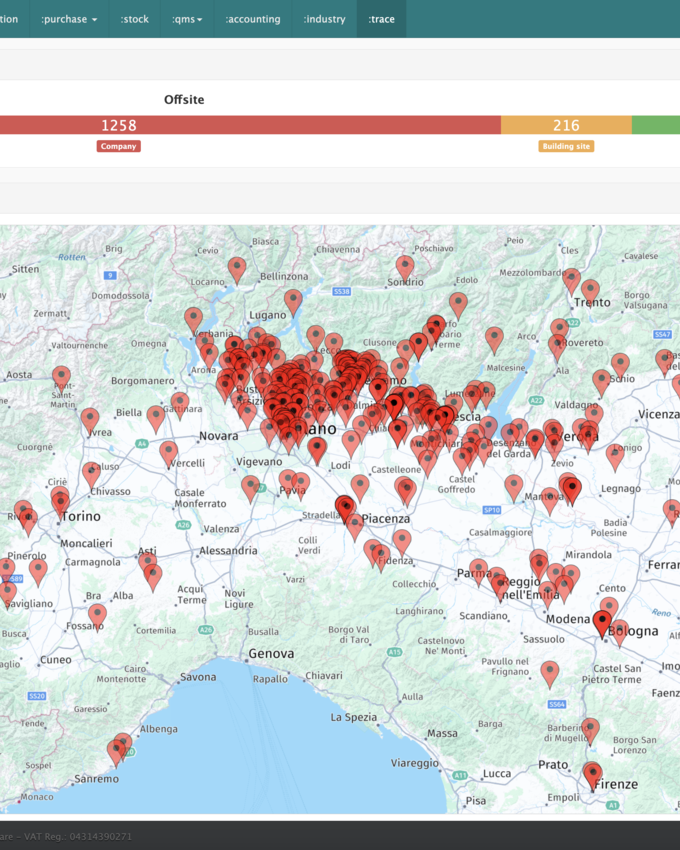

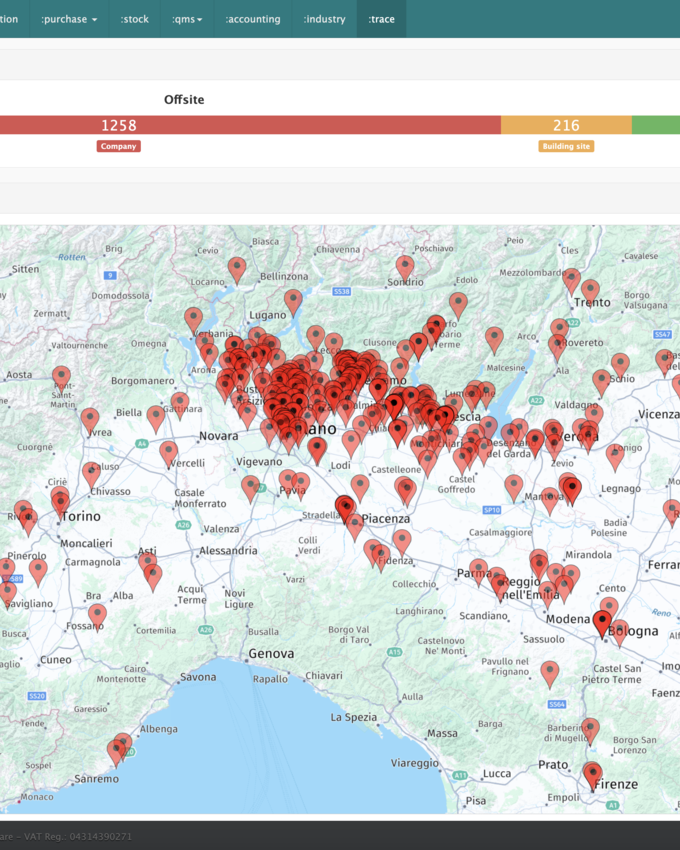

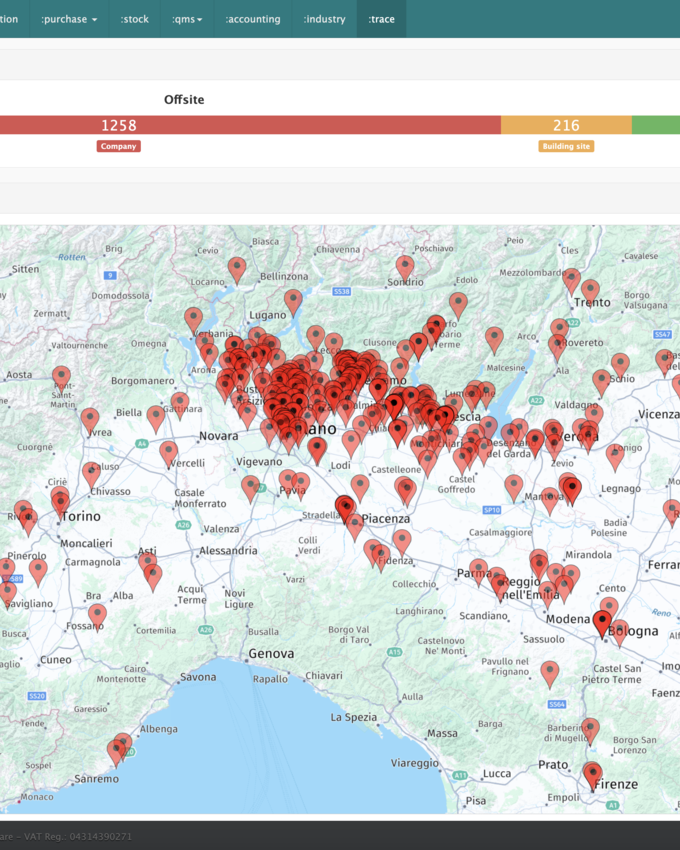

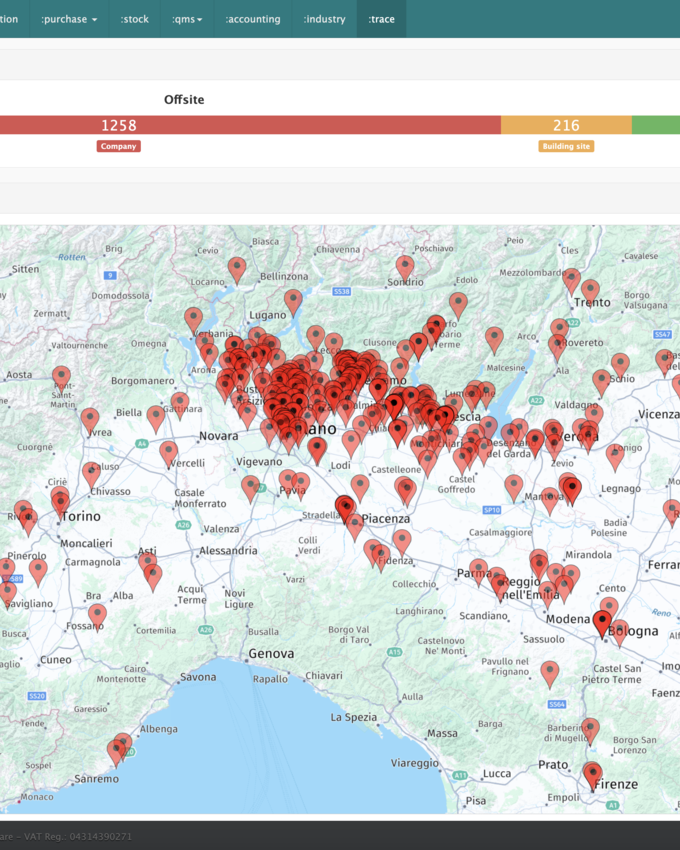

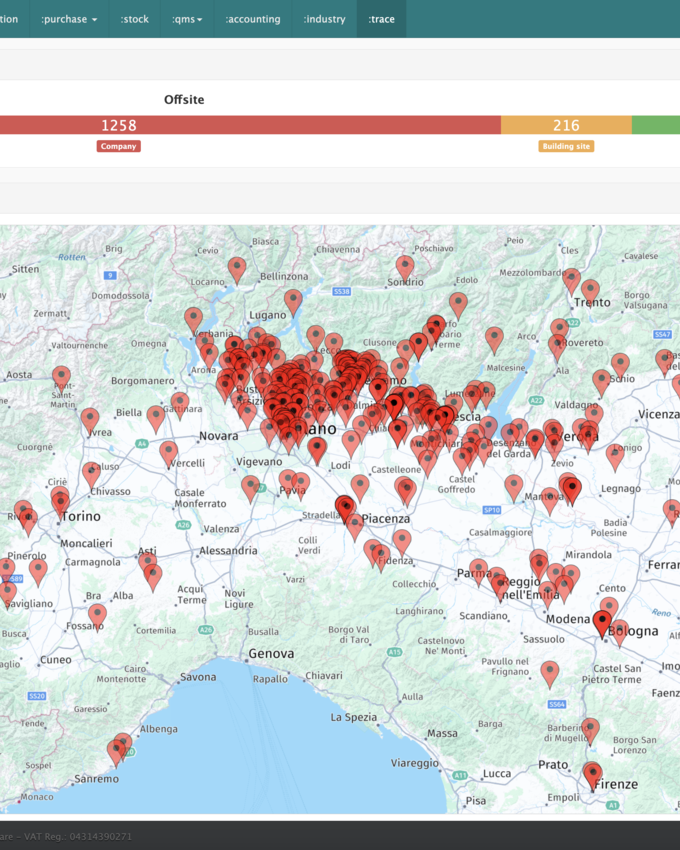

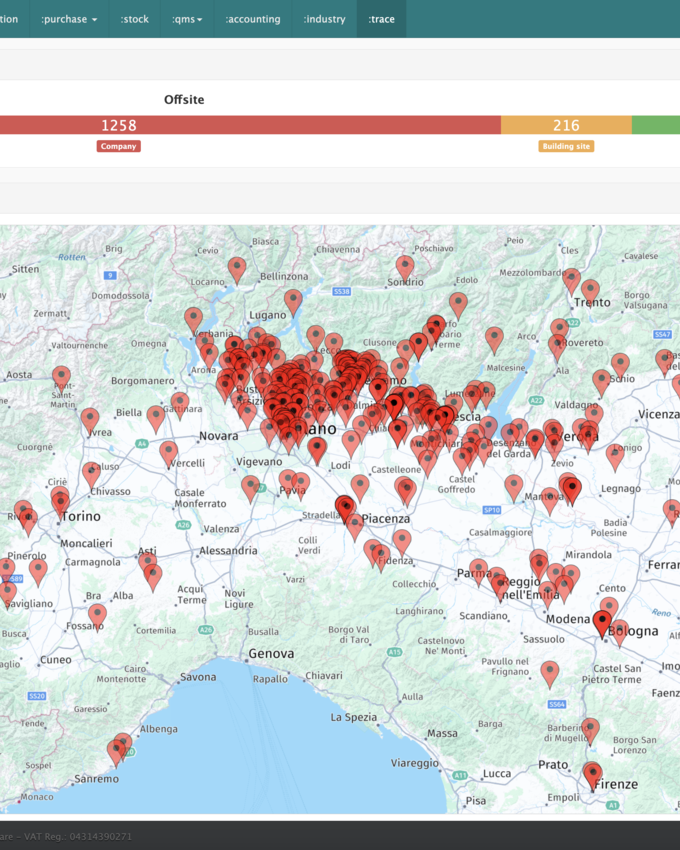

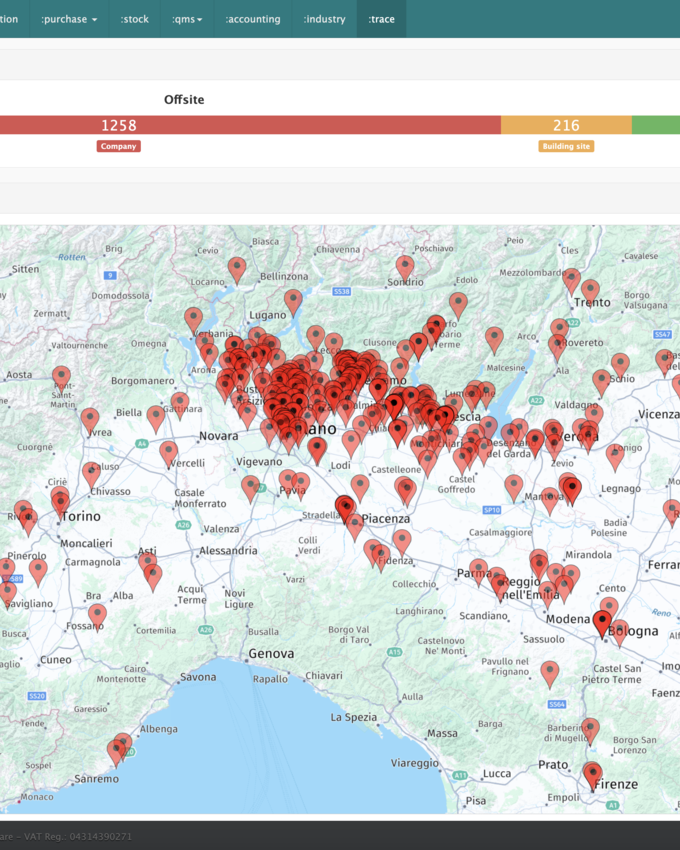

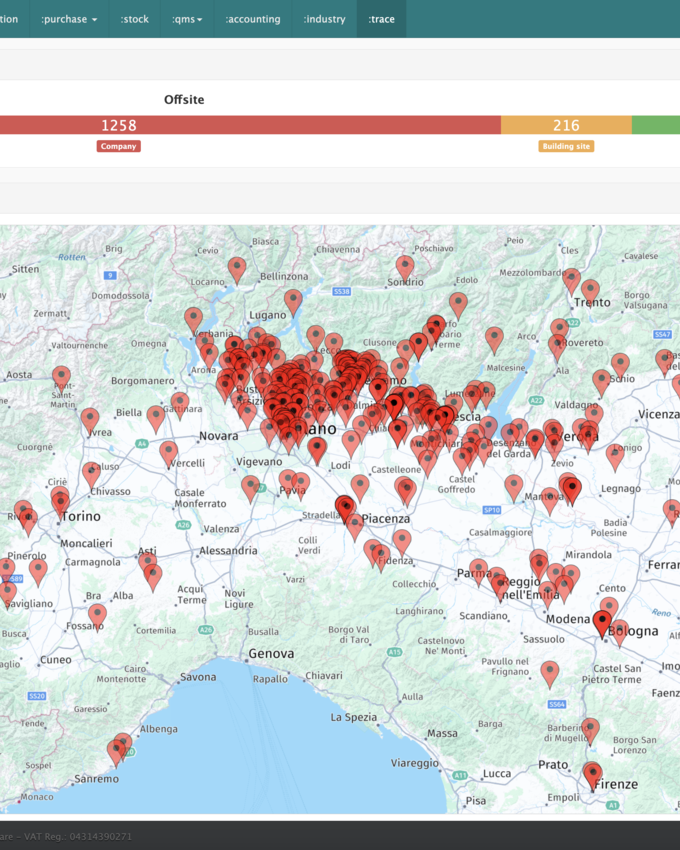

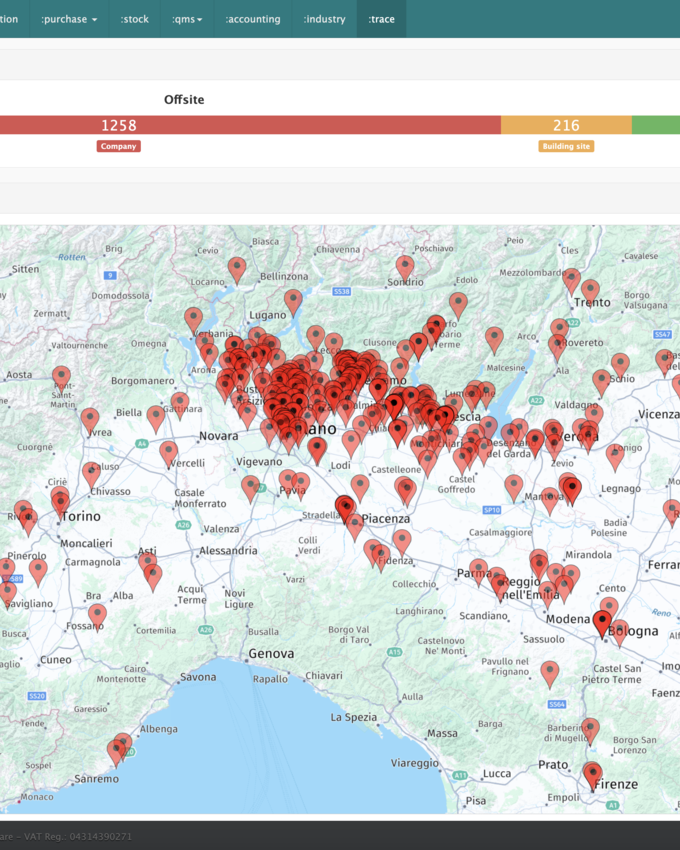

Map tracking and route planning

An interactive map shows the current locations of the racks outside the factory in real time. With the help of advanced search filters, racks can be found by customer, address or duration outside, which significantly simplifies planning and retrieval.

03

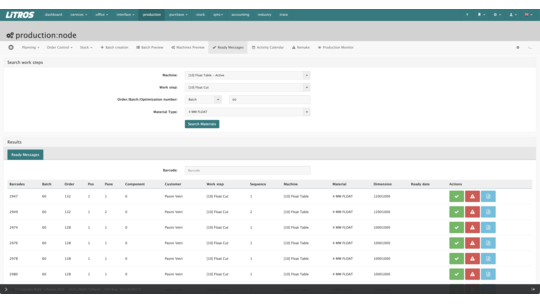

Table view and advanced analytics

All relevant frame information, such as delivery note, customer and departure time, is presented in a clear table. Filtering and sorting functions enable quick analysis, while continuous monitoring automatically highlights overdue returns.

04

RFID add-on

The RFID add-on automates the check-in and check-out of racks using passive RFID tags that recognize movement without manual input. This prevents scan errors and significantly speeds up processes.

05

Geolocation

With LPWAN geolocation via Sigfox or LoRa, IoT trackers send location data even in areas with low network coverage. This continuous monitoring is ideal for long-term external tracking and supports efficient return planning and cost reduction.

06

Scheduling and automated notifications

The system automatically creates scheduled reports that are sent by email, for example on overdue racks or expected returns. Intelligent alerts provide information in the event of anomalies such as late returns and enable proactive action.

07

This is how it works in practice

First, the racks are loaded during the production phase and automatically linked to the corresponding delivery note. When shipped, the racks leave the factory and their movement is detected via RFID or manual scan. While they're outside, the system logs location and duration and marks overdue returns. After returning, the availability of the racks is updated automatically or manually so that they are immediately ready for use again.

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?