Description

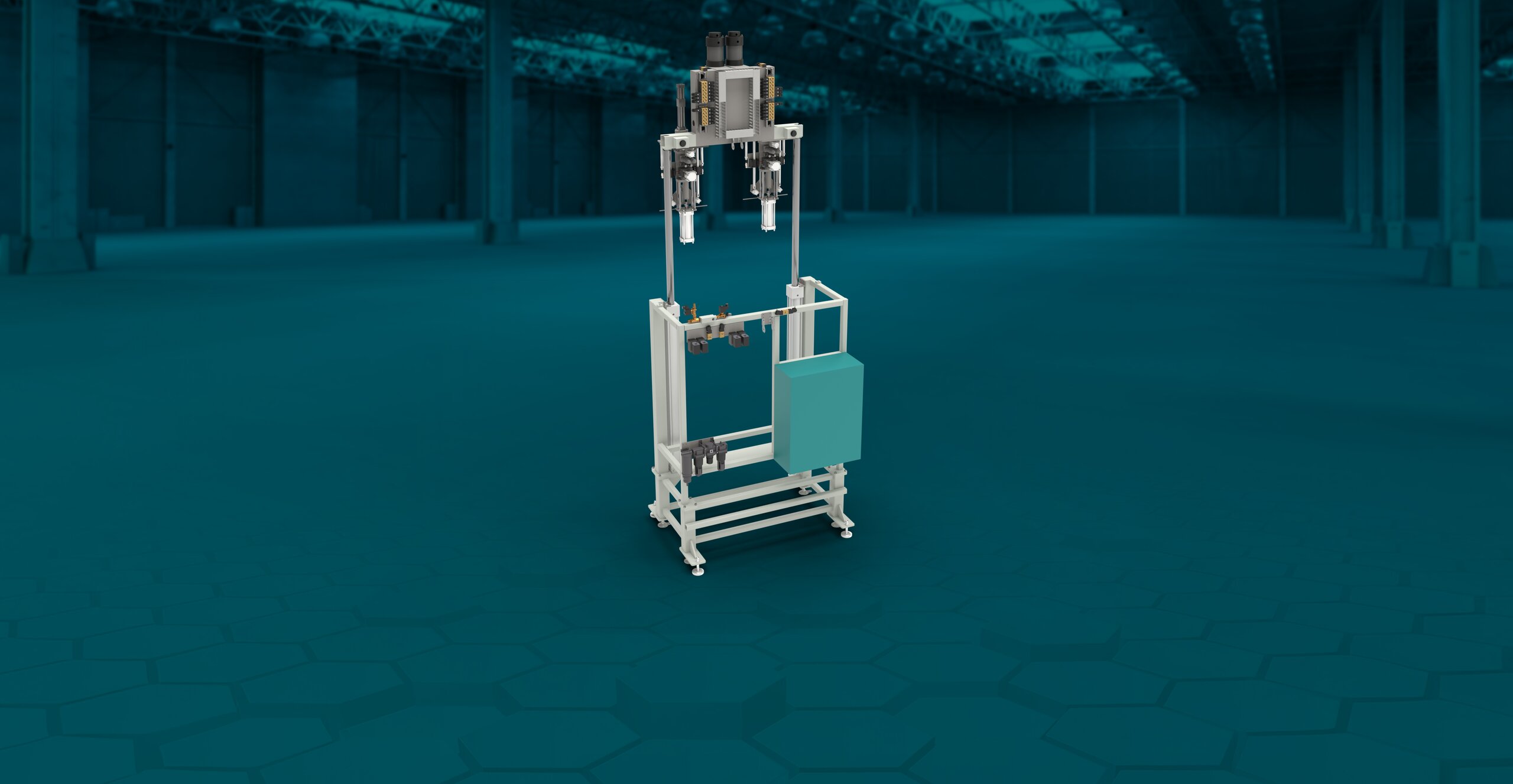

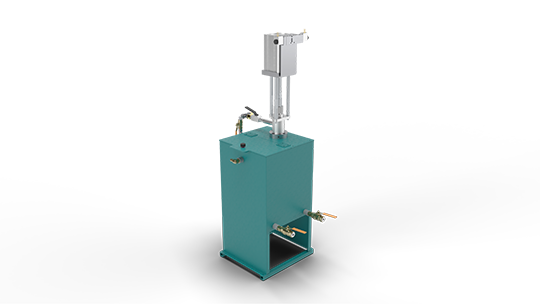

LiTROS IG Desiccant Automatic

The LiTROS IG Desiccant Automatic offers a smart solution for filling fixed spacers with desiccant. This reliable station combines modern technology with a robust design.

The machine consists of:

Height-adjustable filling heads

Two filling heads for shorter cycle times

Two foot pedals to control the filling heads

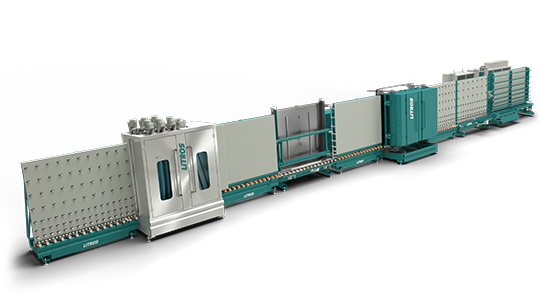

LiTROS insulating stand alone

Highlights

01

Height adjustable filling heads:

Allow flexible adjustment to different frame heights.

Double filling heads:

Reduce cycle time by filling both sides at the same time.

Two foot pedals:

Provide easy control of filling heads.

Sturdy steel construction:

Ensures durability and stability

Pneumatic lifting device:

Enables optimal adjustment of the working height.

Automatic granulate conveying:

Ensures a continuous supply to the filling heads.

Butyl closure:

For reliable sealing of holes.

Perfectly coordinated

Function & procedure

01

Filling device

The spacer frames are manually hooked into the filling device.

02

Lifting device

The optimal working height can then be set using a pneumatic lifting device.

03

Spacer frame

The spacer frame is automatically drilled on the back of the short and long frame handles.

04

Filling equipment

The granulate is automatically conveyed from a 50 kg drum to the filling apparatus and both sides of the spacer frame are filled with granulate at the same time.

05

Caulking

Finally, the holes are securely sealed with butyl. The LiTROS IG desiccant automatic station is therefore a good solution for companies looking for an efficient way to fill and seal spacer frames. With its solid technology and robust design, it ensures that your production processes run smoothly.

Specifications

LiTROS IG Desiccant Automatic

Here you can find all relevant features of our machine.

Max. spacer size (mm): 3600 side length

Min. spacer size (mm): 300 × 300

Spacer width (mm): 5 — 24

Filling speed (sec): 5 — 1000 ×1000 × 12 (spacer width)

Desiccant grain size (mm): 0.5 ~ 0.9 (manual: 1.0 ~ 1.5)

Desiccant container/ barrel (kg): 50

Maximum capacity: (2-head machine) 600 ~ 800 Frame: 1,000×1,000 mm in 8 hours

Voltage and frequency: 2P 380~480 V, 50 or 60 Hz, 1.5 kW

Air pressure (kg/cm²): 8

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?