Description

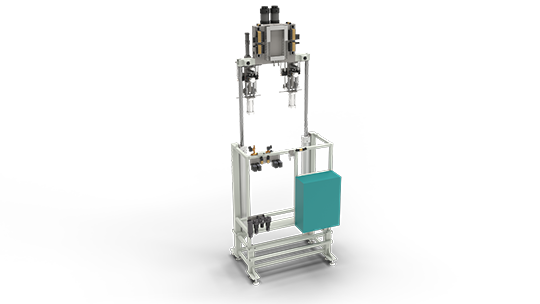

LiTROS IG Seal Manual

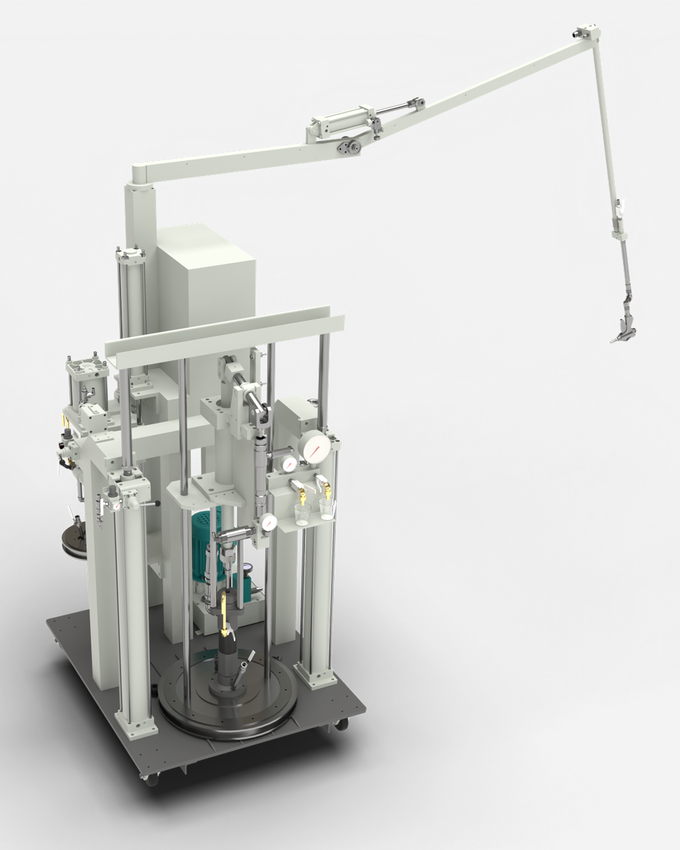

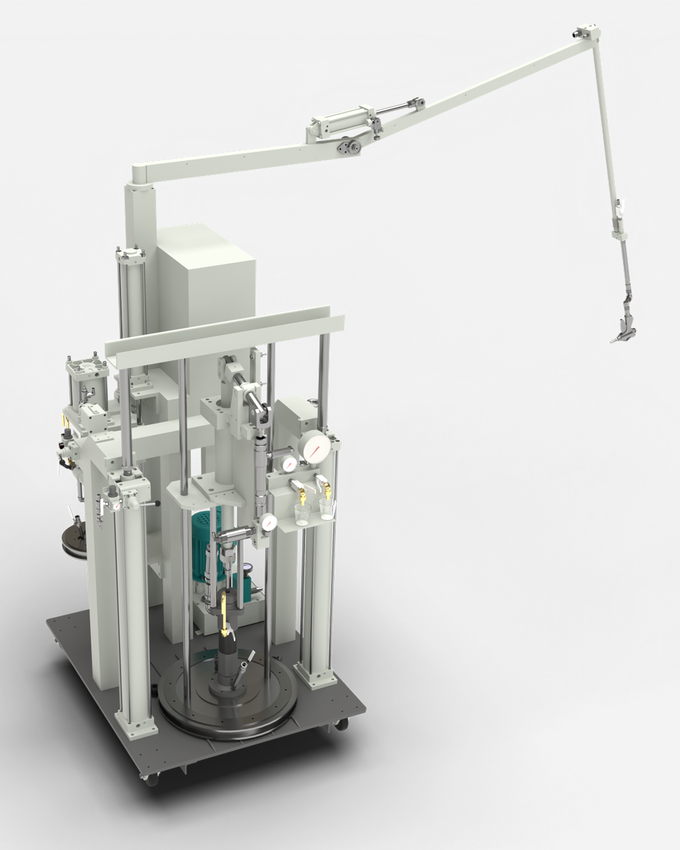

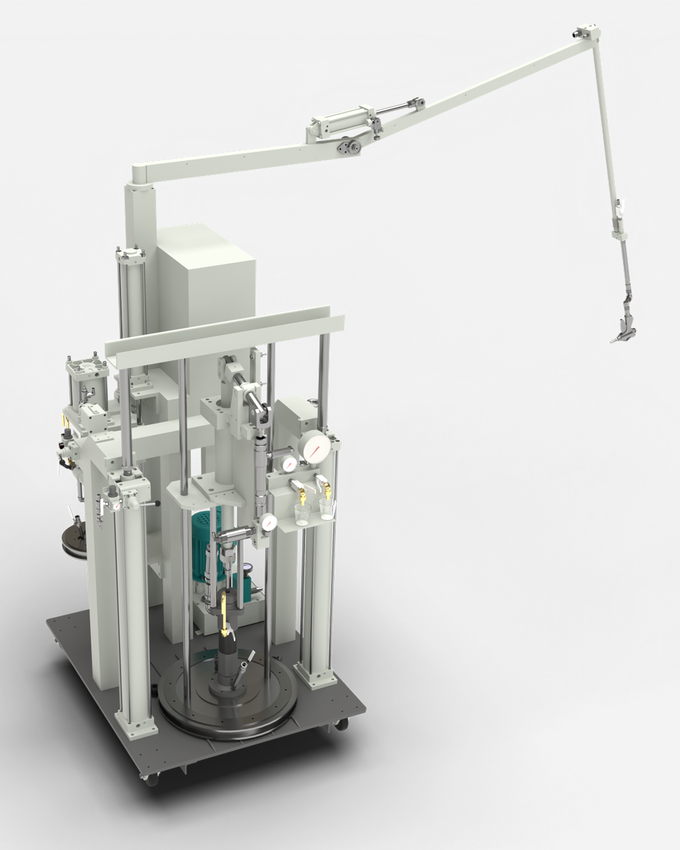

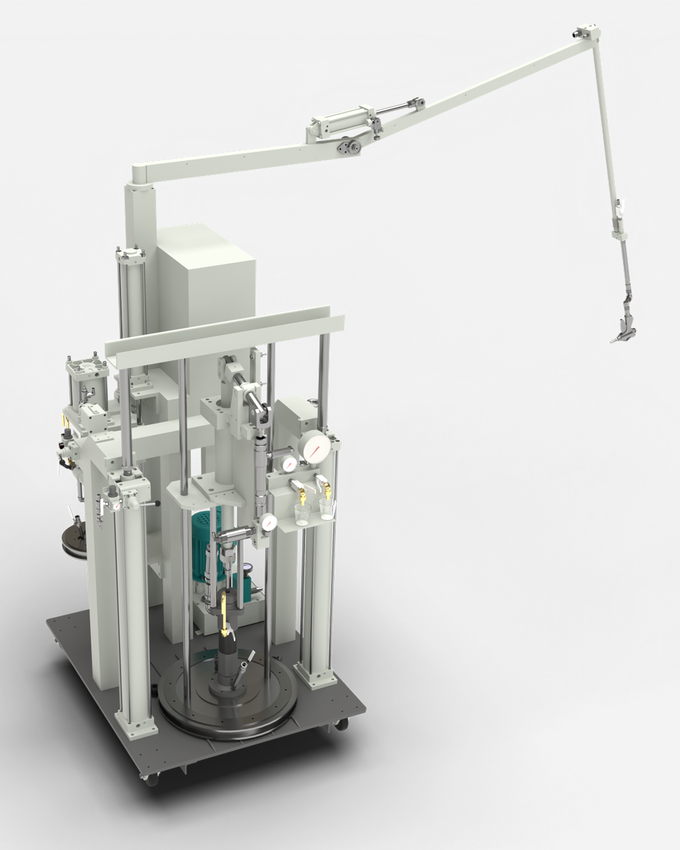

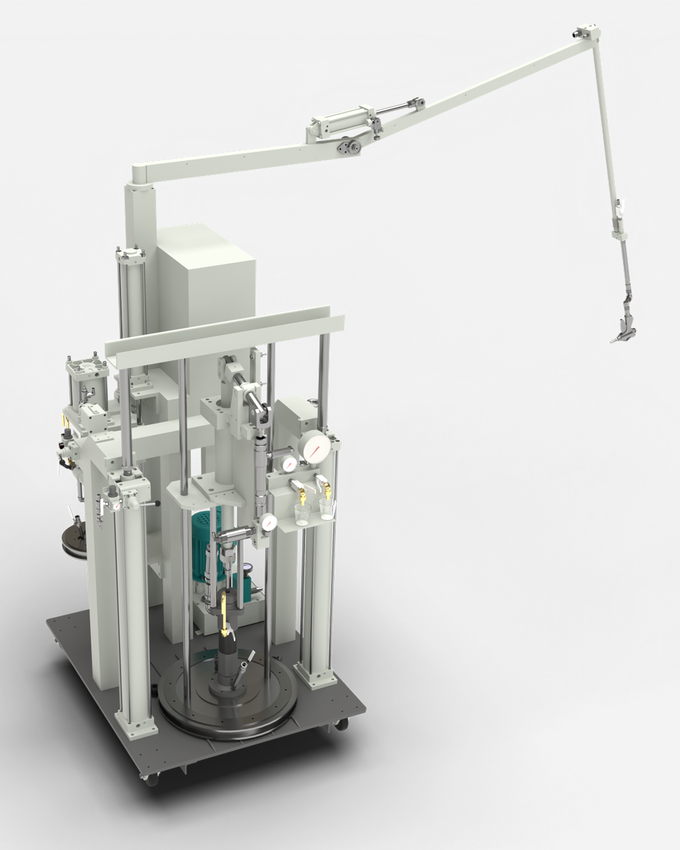

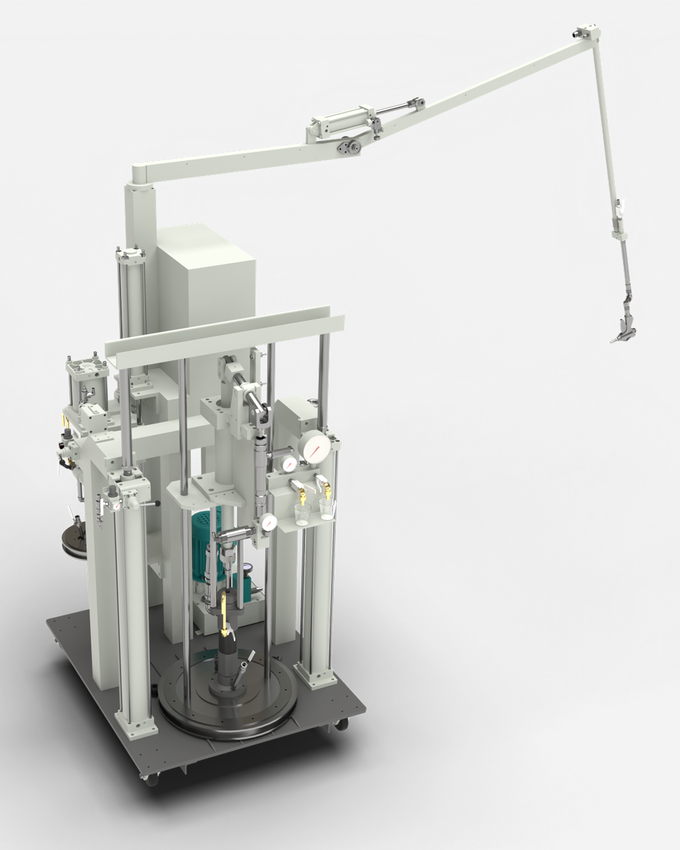

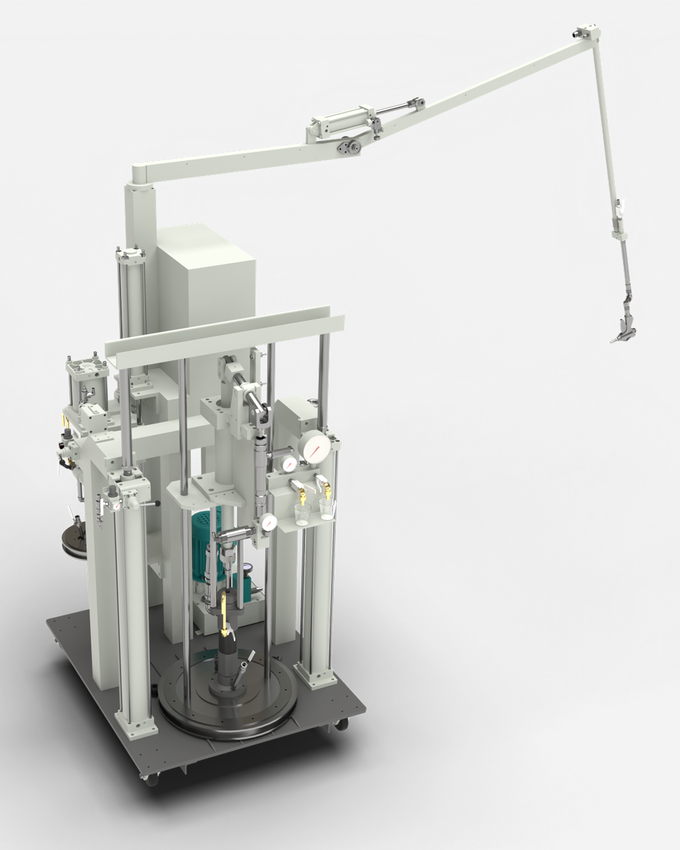

The LiTROS IG seal manual provides an efficient solution for the manual application of secondary sealants in insulating glass production. This system combines modern technology with a robust design to ensure reliable use.

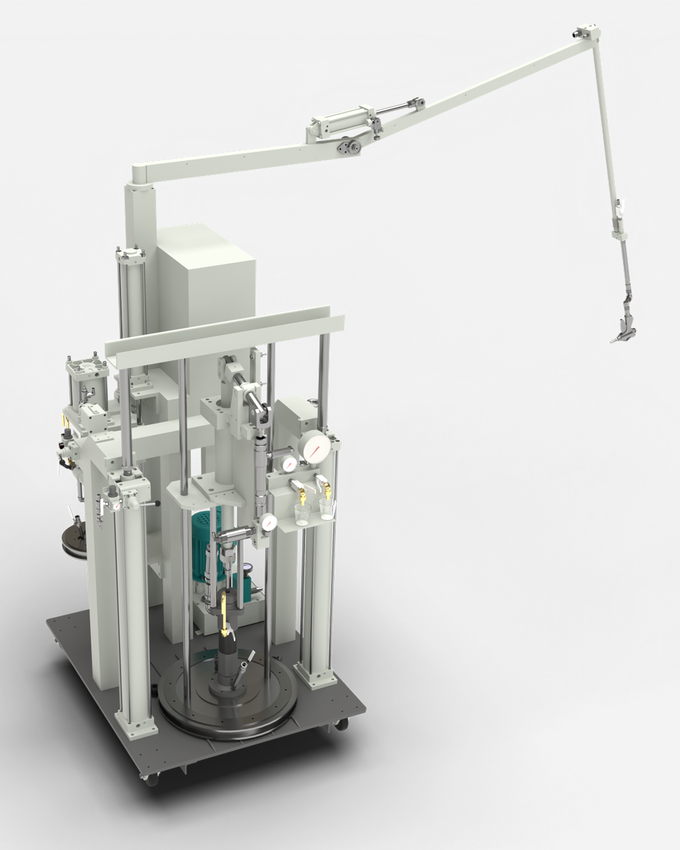

Components of the system:

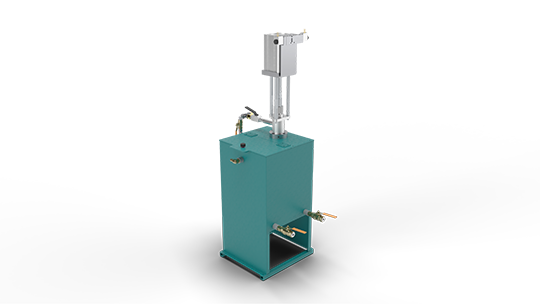

Hardener pump

Base pump

Cantilever arm including material guide

Dosing gun for exact application of the sealant

LiTROS insulating stand alone

Highlights

01

Precise dosing:

The system enables precise dosing of the required materials, which results in a uniform and high quality application.

Cost efficiency and easy maintenance:

Thanks to the easy to change plastic mixer and robust construction, the system is both cost effective and easy to maintain.

High flow rate:

The hydraulic pumping system ensures a high flow rate and powerful material application.

Safety check valve:

An integrated high pressure safety check valve protects the system and increases operational safety.

Perfectly coordinated

Function & procedure

01

Separate hardener and base pumps

With the LiTROS IG seal manual, secondary sealants can be applied according to a well thought out principle. Separate hardener and base pumps ensure precise dosing of the required materials.

02

Dosing pump

A special dosing pump ensures a uniform flow of material without pressure fluctuations, which results in a constant and clean application of the sealant.

03

Hose mixing system

The hose mixing system is equipped with an easy to change plastic mixer, which is cost effective and easy to maintain.

04

Hydraulic pumping system

A hydraulic pumping system ensures a high flow rate and powerful material application.

05

High pressure safety check valve

In order to increase operational safety, an integrated high pressure safety check valve automatically initiates recirculation in the event of overpressure. The LiTROS IG seal manual is therefore a good solution for companies looking for a cost effective and reliable method for the manual application of secondary sealants. With its robust technology and robust design, it ensures that your production processes run smoothly and efficiently.

Specifications

LiTROS IG Seal Manual

Here you can find all relevant features of our machine.

Mixing ratio: 8:1 ~ 12:1

Voltage and frequency: 3P 380~480 V, 50 or 60 Hz, 3.2 kW

Maximum pressure: 250 kg/cm²

Drum capacity: part A (base): 200 liters, part B (hardener): 20 liters

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?