Description

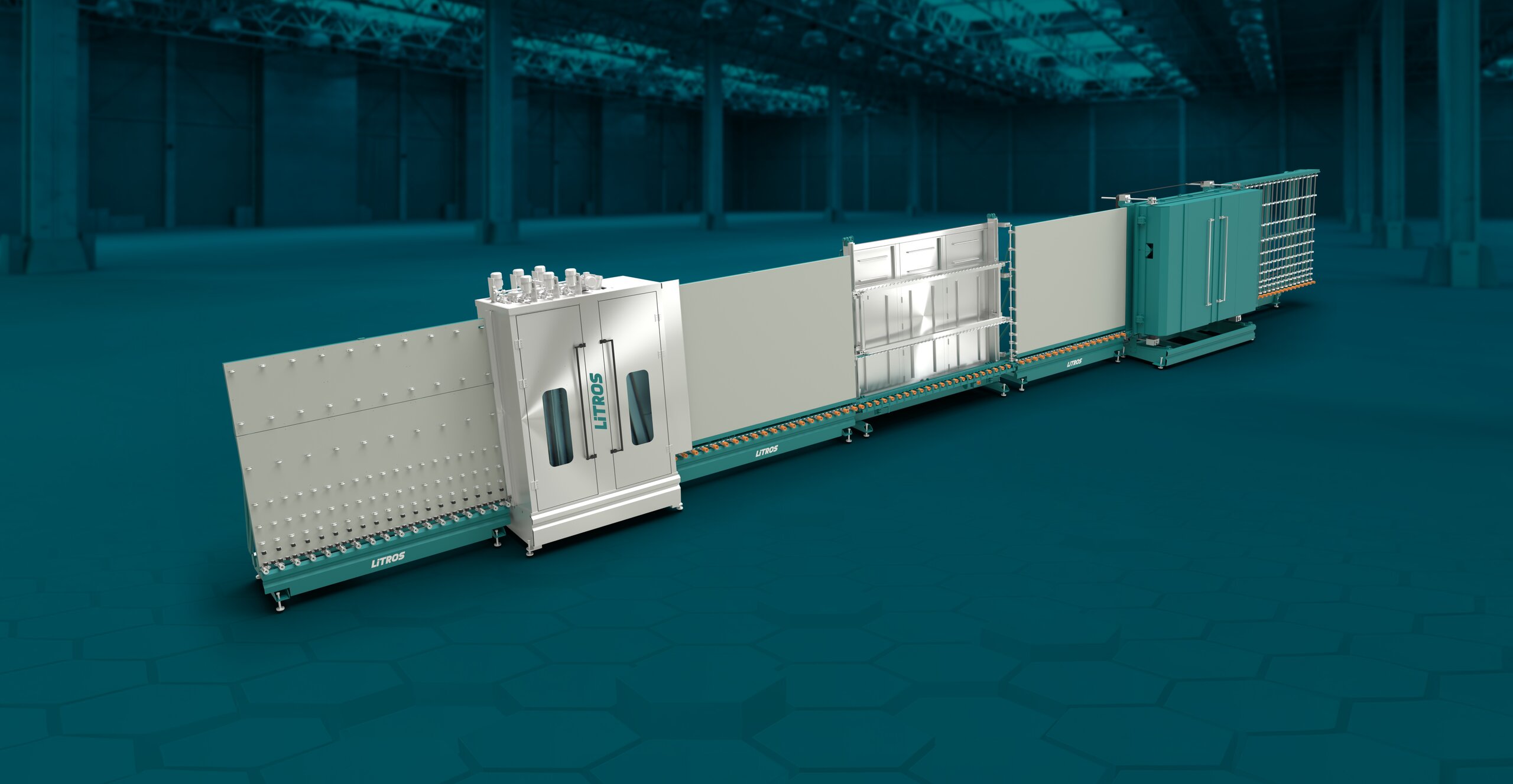

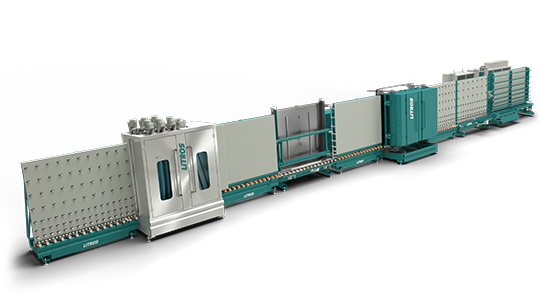

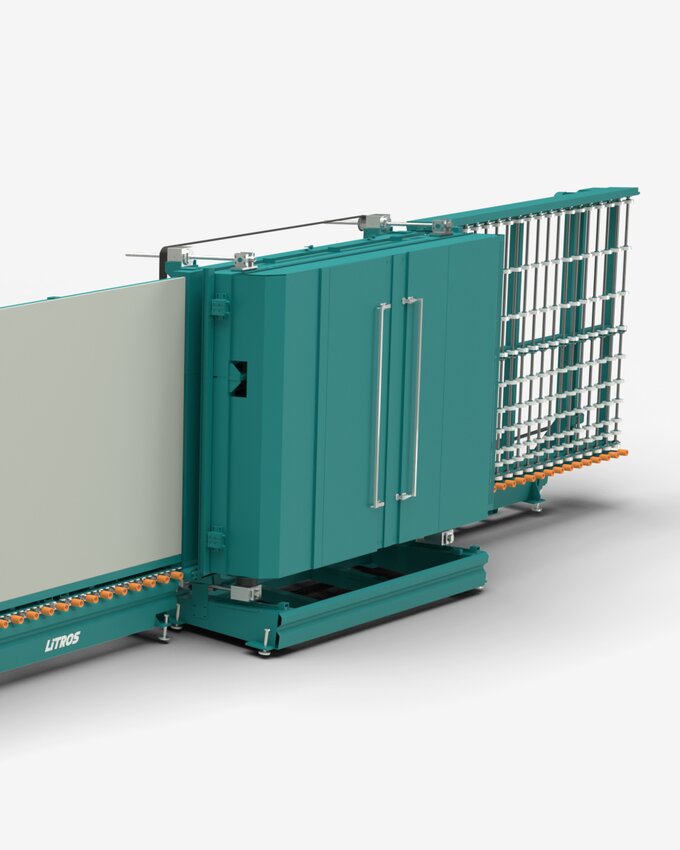

LiTROS IG Line Rigid

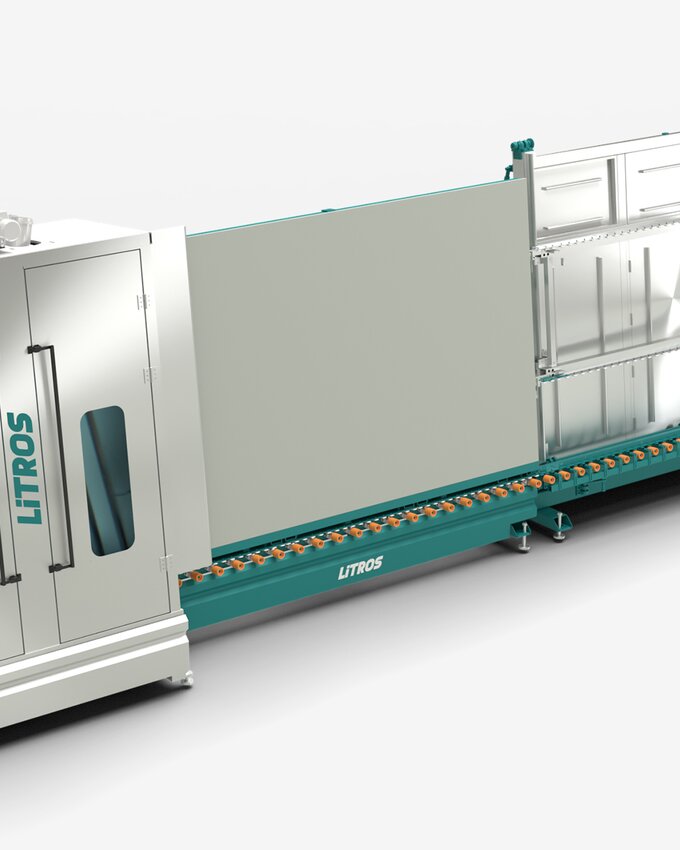

The vertical LiTROS insulating glass line offers a good solution for the efficient production of insulating glass units with rigid spacer frames. It combines solid technology with a sophisticated and robust design. Reliability and ease of use are guaranteed. The line is available in three different versions, which relate to the maximum processing size:

- 2400 mm x 1800mm

- 3600 mm x 2400 mm

- 6000 mm x 3000mm

Components of the insulated glass line:

Transport station with wheels

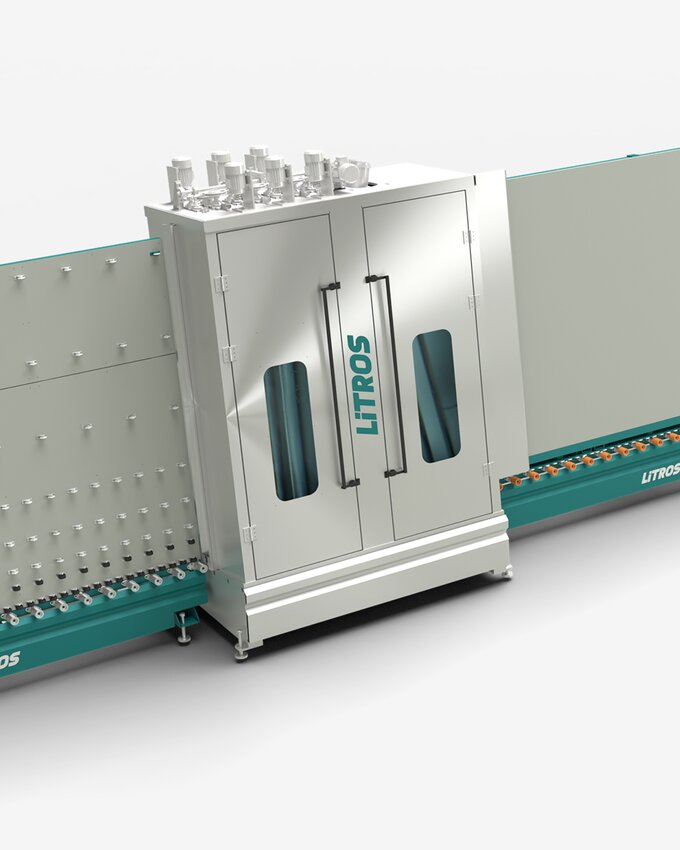

Washing machine

Transport station with air cushion

Inspection and manual frame positioning station

Transport station with air cushion

Assembly press

Transport station with wheels

Automatic tipping station

LiTROS insulating line

Highlights

01

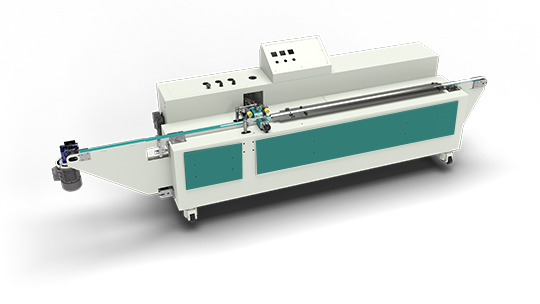

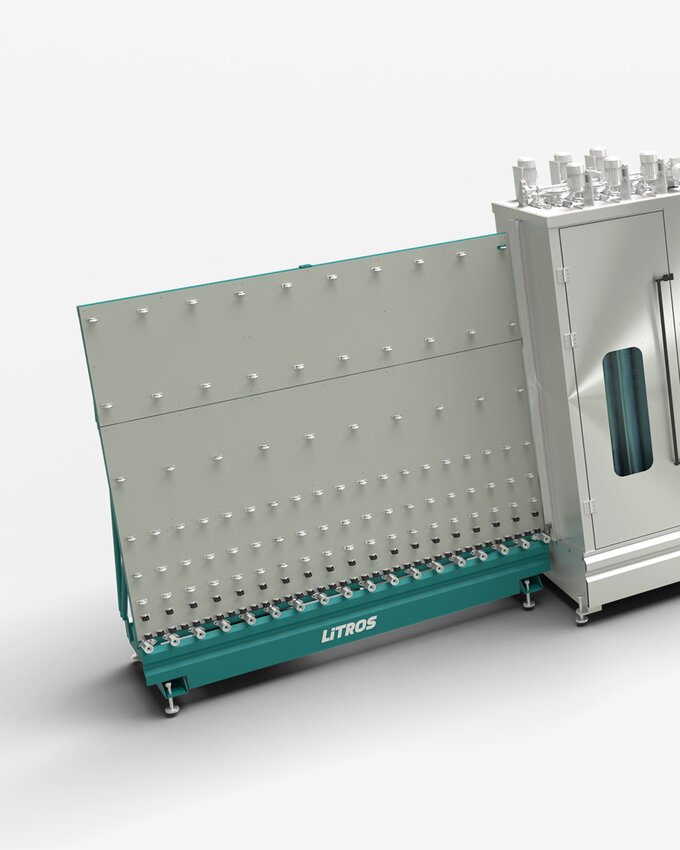

Washing machine:

The washing machine is made of sturdy, water resistant stainless steel and aluminum. These materials ensure optimum durability and corrosion resistance of the machine. Even with continuous use, it withstands humid environments.

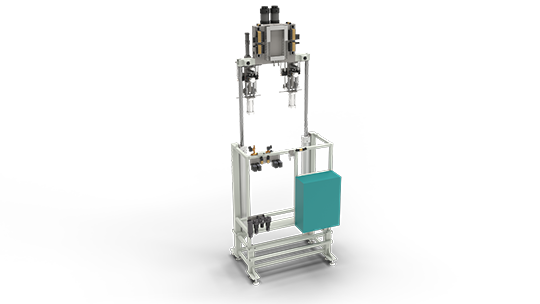

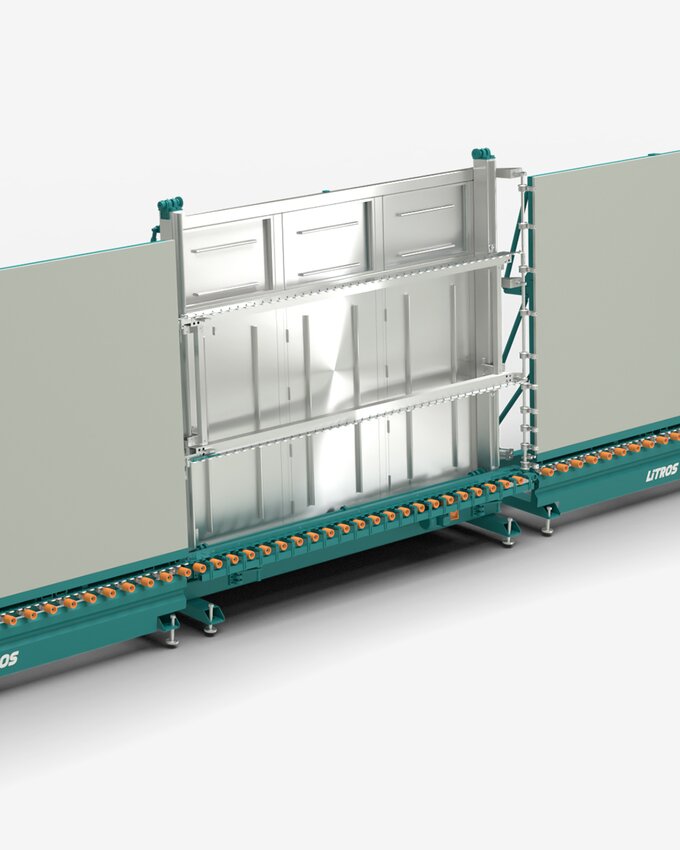

Frame setting station with vision function:

An automatically controlled support bar recognizes the top edge of the glass and adjusts itself with the aid of sensors. It is combined with an intelligent wheel system that supports the windshield out of sight.

Assembly press:

Pressure control via spindle drives with servomotors ensures uniform power transfer.

Perfectly coordinated

Sophisticated stations

01

Transport station with glass transport rollers

A sturdy, painted steel frame and an automatic system for detecting Low E coatings ensure a smooth start. The chain driven transport rollers are precisely synchronized with the downstream washing and drying system. This ensures a smooth production process without interruptions.

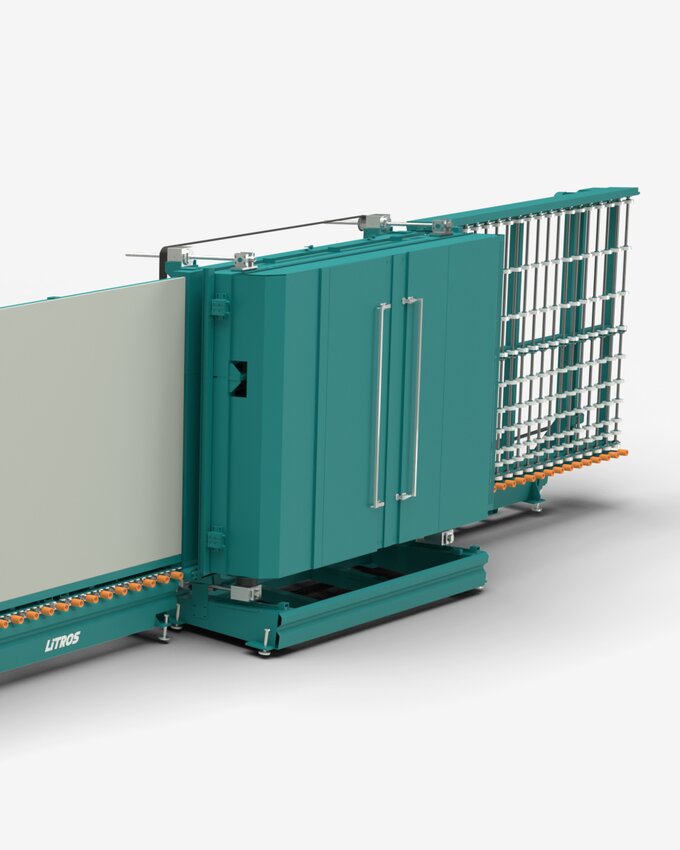

02

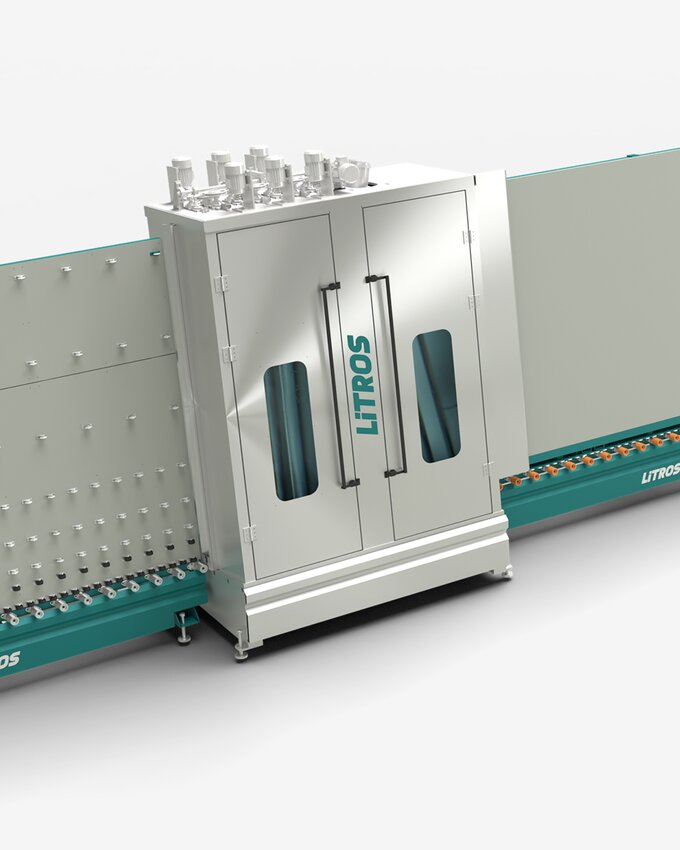

Glass washing and drying plant

Three pairs of powerful nylon brushes, two removable water collection tanks and a separately heated heating tank with a circulation pump guarantee thorough and gentle cleaning. Inspection doors with viewing windows keep an eye on the cleaning process at speeds of up to 12 m/min.

03

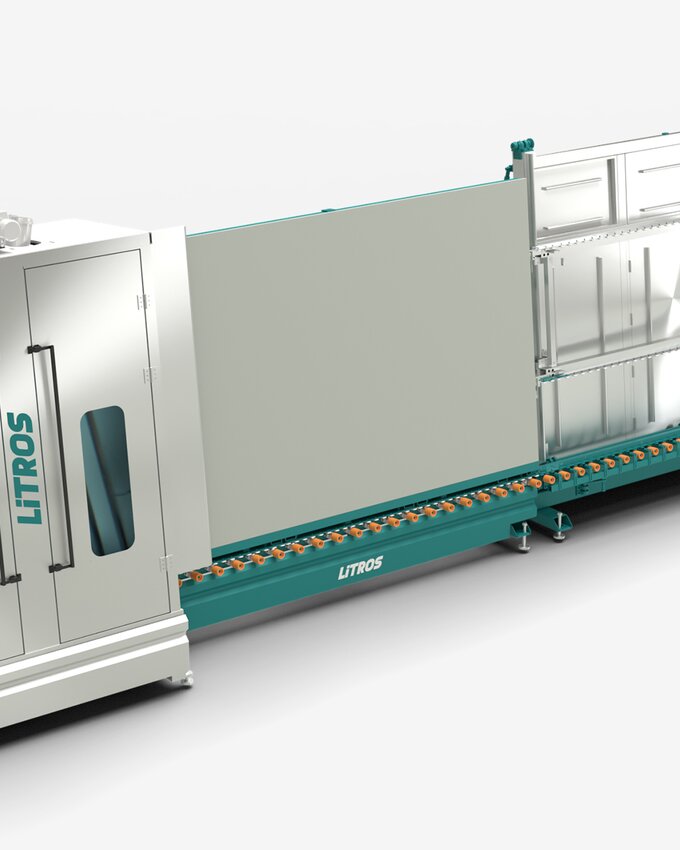

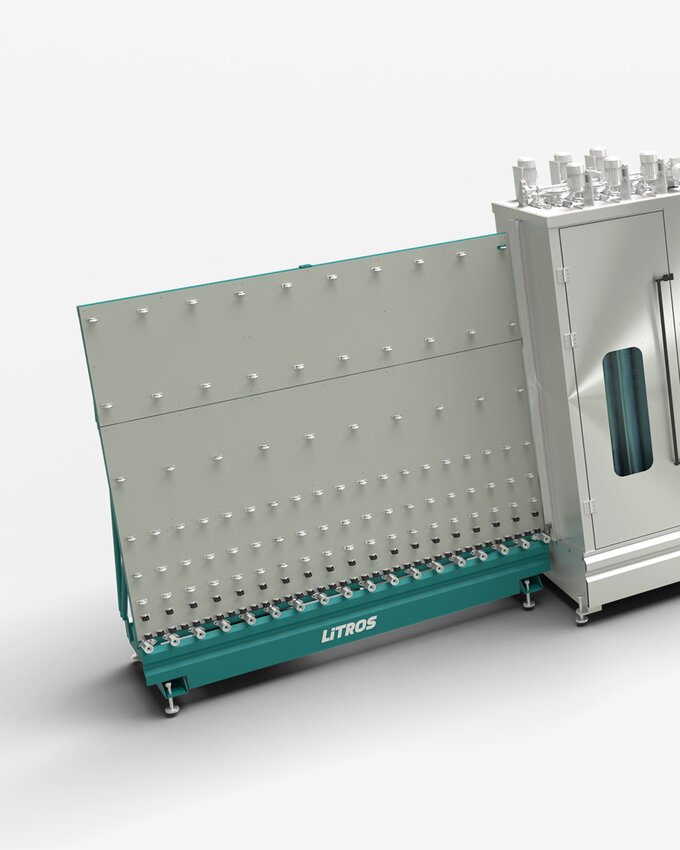

Hoverbag transport station

The perfect combination of chain driven roller transport and air cushion technology allows the glass panes to be moved gently and effortlessly. An integrated fan protects sensitive surfaces and makes the transition to the next station easier.

04

Inspection and frame positioning station

Bright, non reflective lighting in the rear area supports manual visual inspection. At the same time, rear access doors allow easy cleaning and maintenance for uncompromising quality for every window.

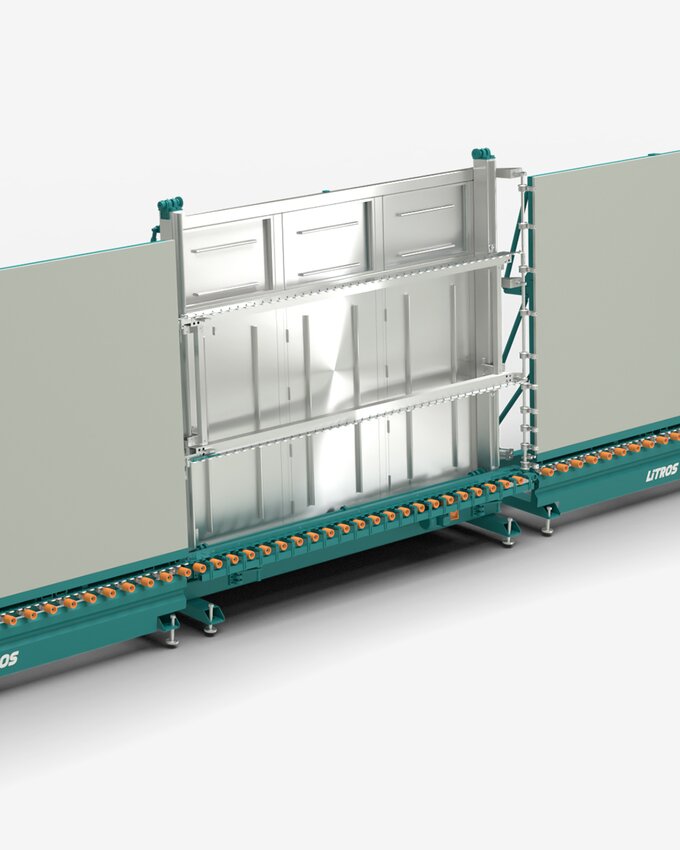

05

Assembly press

Thanks to a sturdy steel frame and modern servo technology, the press automatically adapts to different element sizes. The front panel can be opened by 500 mm, which significantly simplifies service and inspection. A ball screw system ensures even pressure and a perfect end result.

Working direction: Left to right or right to left

Minimum glass size: 400 mm x 200 mm

Glass thickness: 3 - 12 mm/3 - 30 mm (optional)

Unit thickness: 12 - 60 mm

Unit types: rectangles,

dual units,

3 page steps (optional), 4 page steps (optional)

Electrical voltage and frequency: 3P 380-480 V, 50-60 Hz, 60 kW

General transport speeds: 43 m/min

Washer speed: 2 - 12 m/min

Gas filling: optional

Shapes: optional

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?