Description

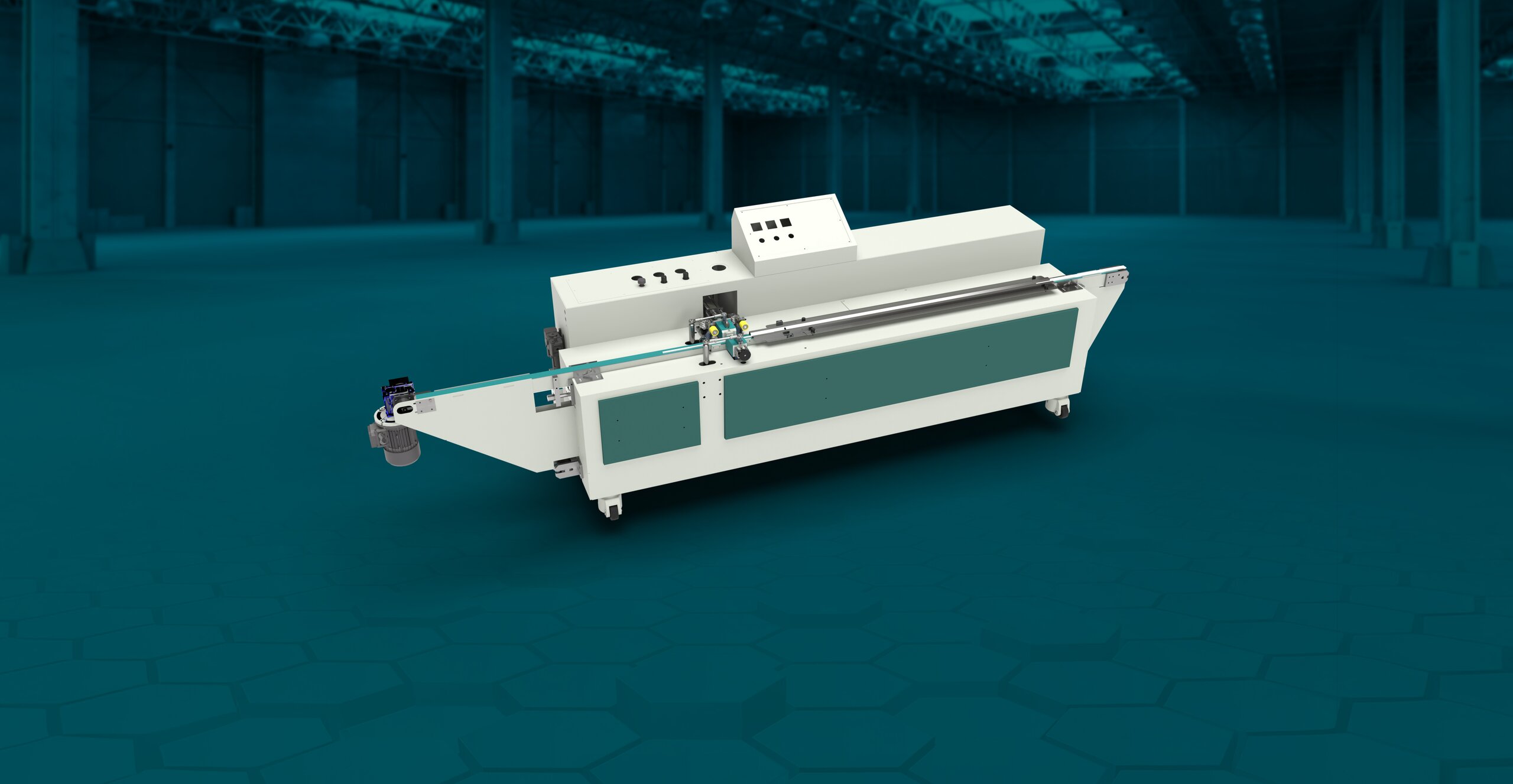

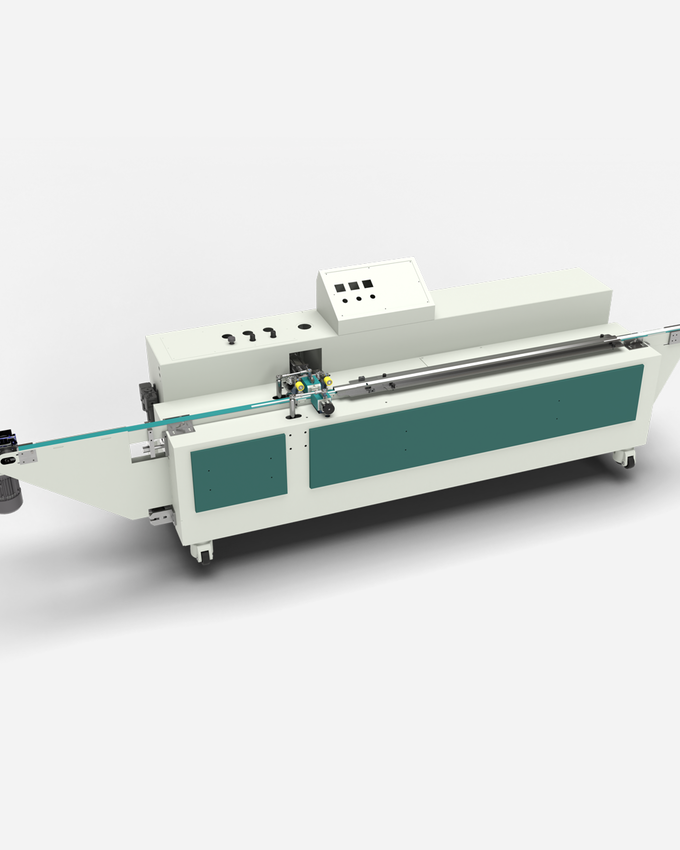

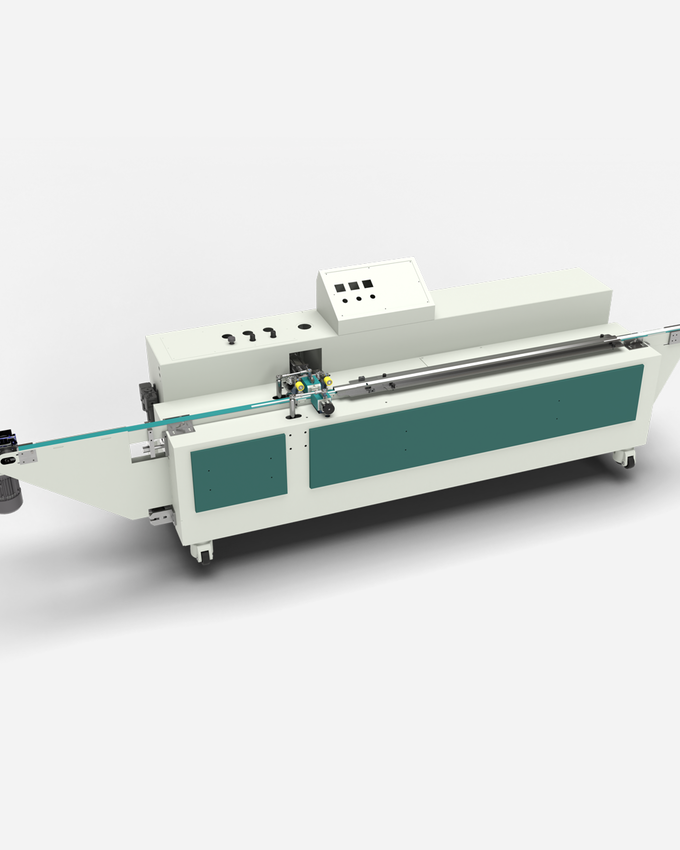

LiTROS IG Butyl Semi Automatic

The LiTROS IG butyl semi automatic provides an efficient solution for coating spacers with butyl hot melt adhesive. This easy to use station combines robust technology with sophisticated design.

Components of the system:

Butyl storage

Application nozzle

Stabilization rollers

Transport belts

LiTROS insulating stand alone

Highlights

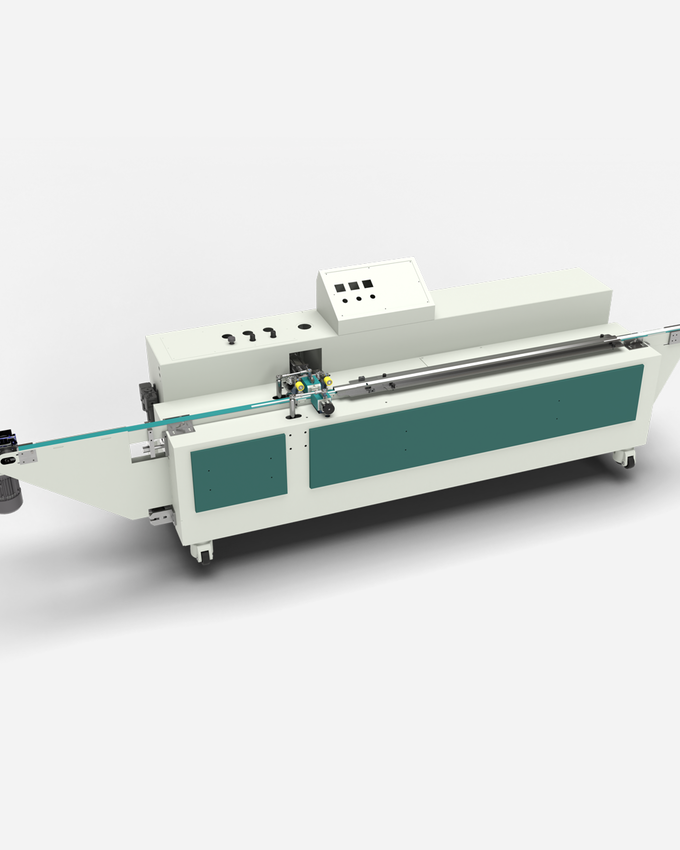

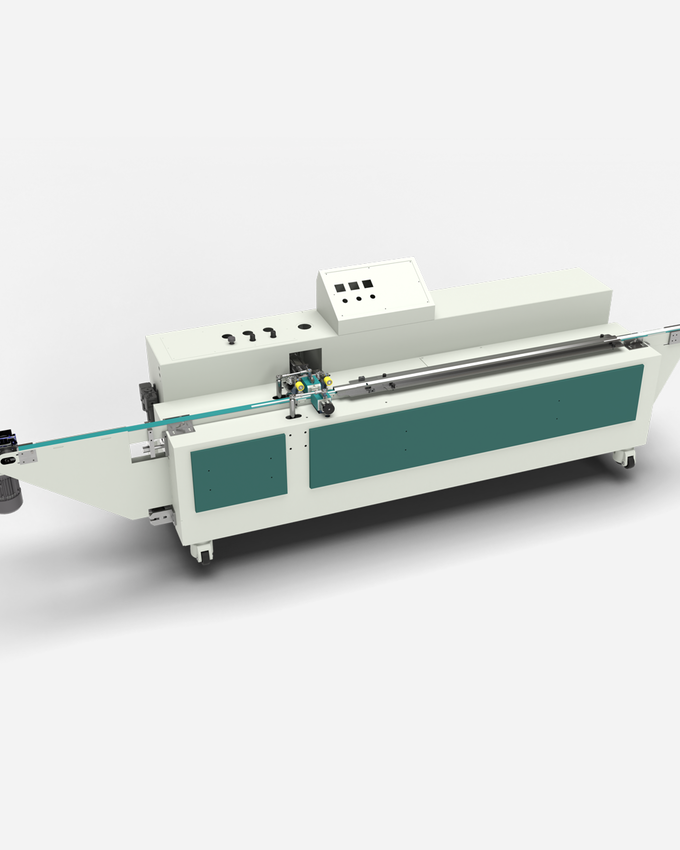

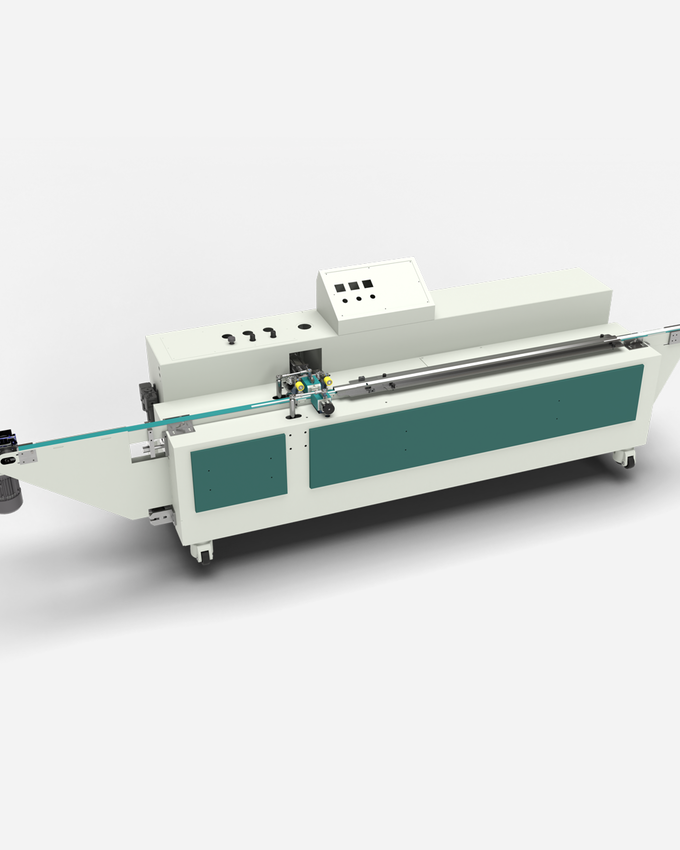

01

Precise guidance:

Stabilization rollers ensure accurate application.

Automatic nozzle adjustment:

The nozzles automatically adjust to the thickness of the spacer.

Touch screen operation:

Easy and intuitive operation via a touchscreen.

Perfectly coordinated

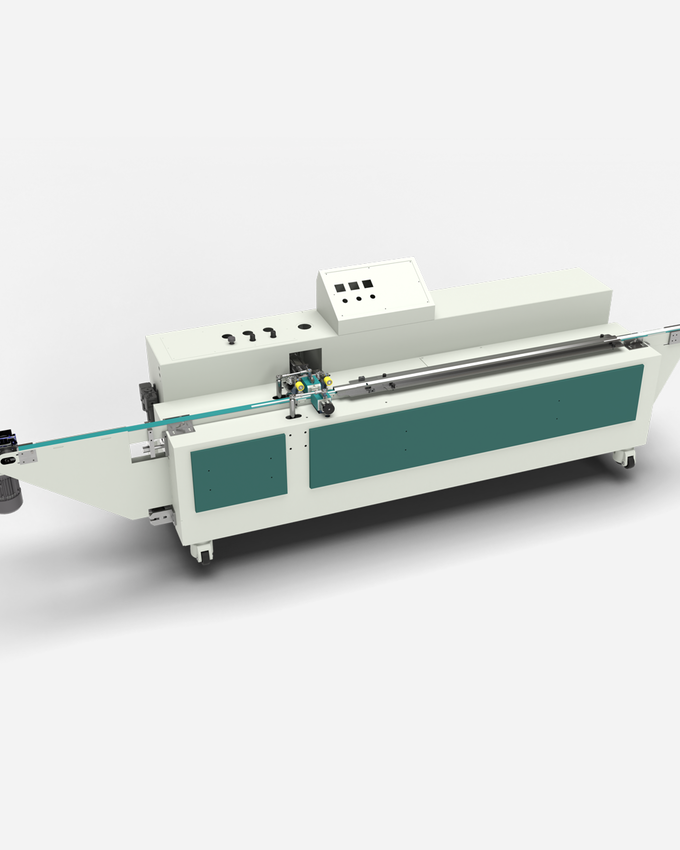

Function & procedure

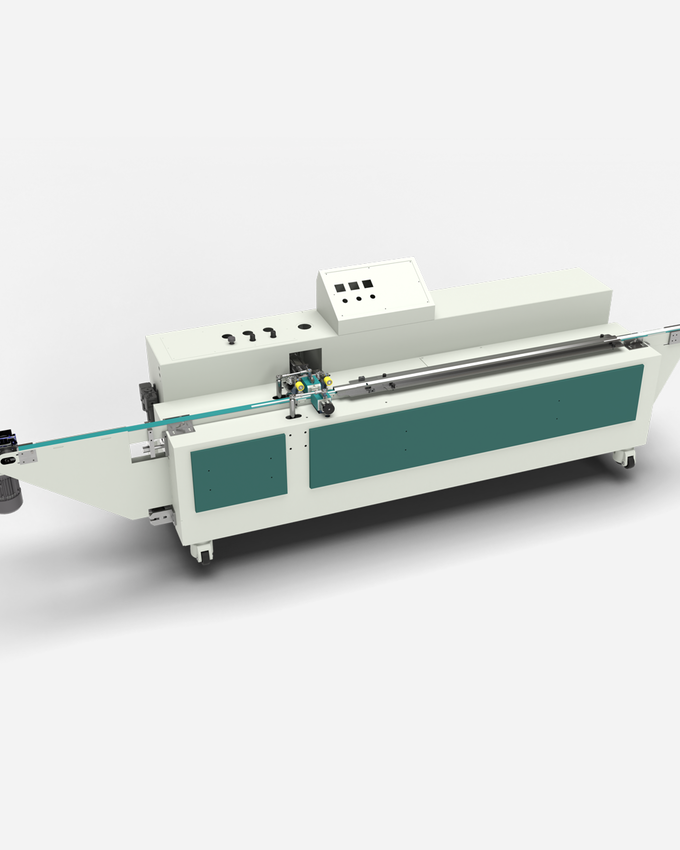

01

Spacer

The spacer is manually pressed against a transport belt and transported to the application nozzle.

02

Application process

During the application process, the spacer frame is guided by stabilization rollers to ensure precise coating.

03

Nozzles

The nozzles automatically adjust to the thickness of the spacer, which ensures uniform application.

04

Touchscreen

It is operated via a touchscreen. For companies looking for a reliable and efficient way to coat spacers with butyl hot melt adhesive, the LiTROS IG Butyl Semi Automatic is a great choice.

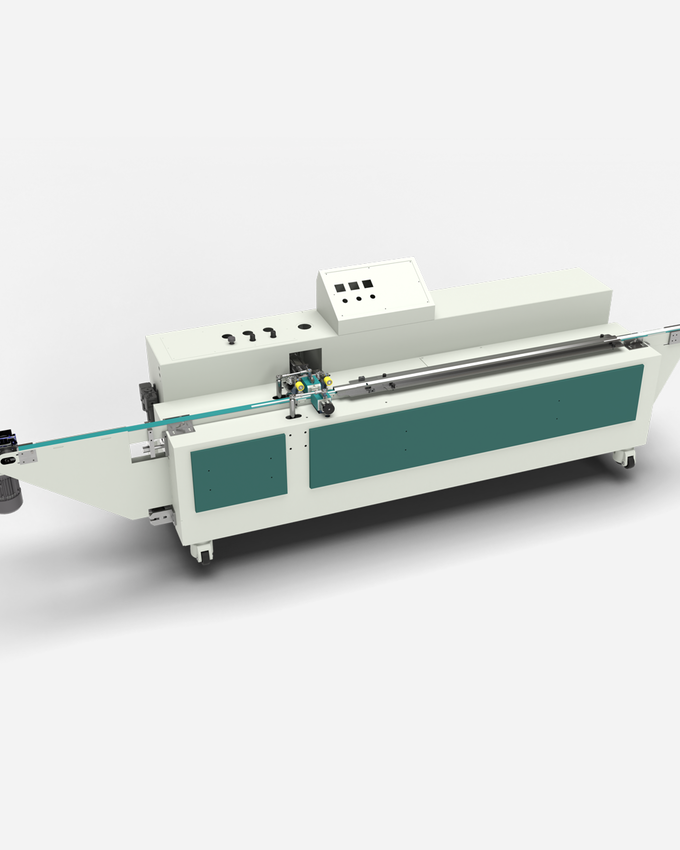

specifications

LiTROS IG Butyl Semi Automatic

Here you can find all relevant features of our machine.

Conveyor speed: 30 m/min

Voltage and frequency: 3P 380~480 V, 50 or 60 Hz, 3.2 kW

Compressed air: 6 kg/cm²

Machine height: 800 mm

Machine length: 3,100 mm

Machine depth: 800 mm

working height: 600 mm

Operating language: English

LiTROS

Product available in the following countries

CONTACT

Do you have any questions or do you need information on this topic?